Rimac Nevera

Rimac presents the Nevera, the production version of the C_Two presented in Geneva in 2018. This second electric supercar from the Croatian company succeeds the Concept_One. This electric sports car, limited to eight units, gained particular notoriety following an accident involving British TV presenter Richard Hammond at a hillclimb in Switzerland. However, neither the Concept_One nor the new Nevera deserve this kind of negative press coverage. Actually, the newcomer was supposed to debut at the 2020 Geneva International Motor Show. After this car show had to be cancelled at short notice due to the onset of the Corona pandemic, Rimac took all the more time to finish developing all the car’s components.

Named after a sudden, powerful storm

With various prototypes, Rimac ensured excellent handling, the best possible brakes and a response of the electric motors so that every customer can use the power. After all, full torque is available from the slightest touch of the gas pedal and doesn’t build up over a long rev band. Added to this is the world’s first driving coach with artificial intelligence, which shows the driver the ideal line, best possible braking points and further potential for improvement during visits to the racetrack. At the same time, company founder Mate Rimac went in search of a suitable model name. He found what he was looking for on his own doorstep: Nevera is a Croatian expression for a sudden, powerful Mediterranean storm over the open sea.

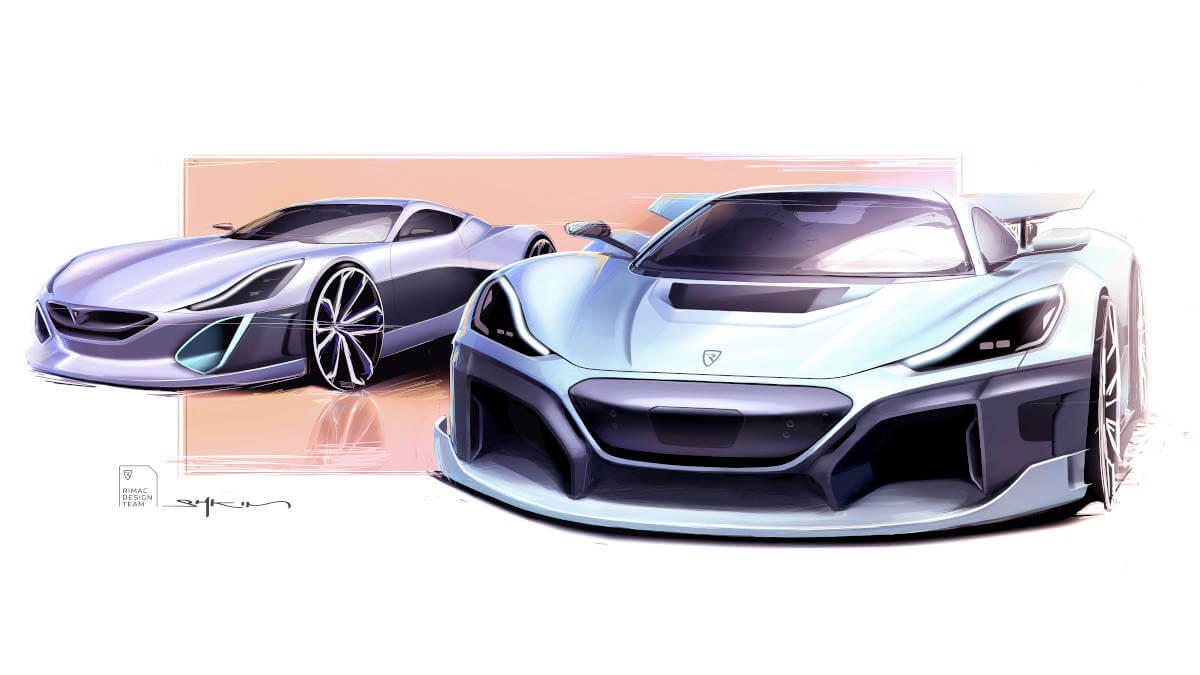

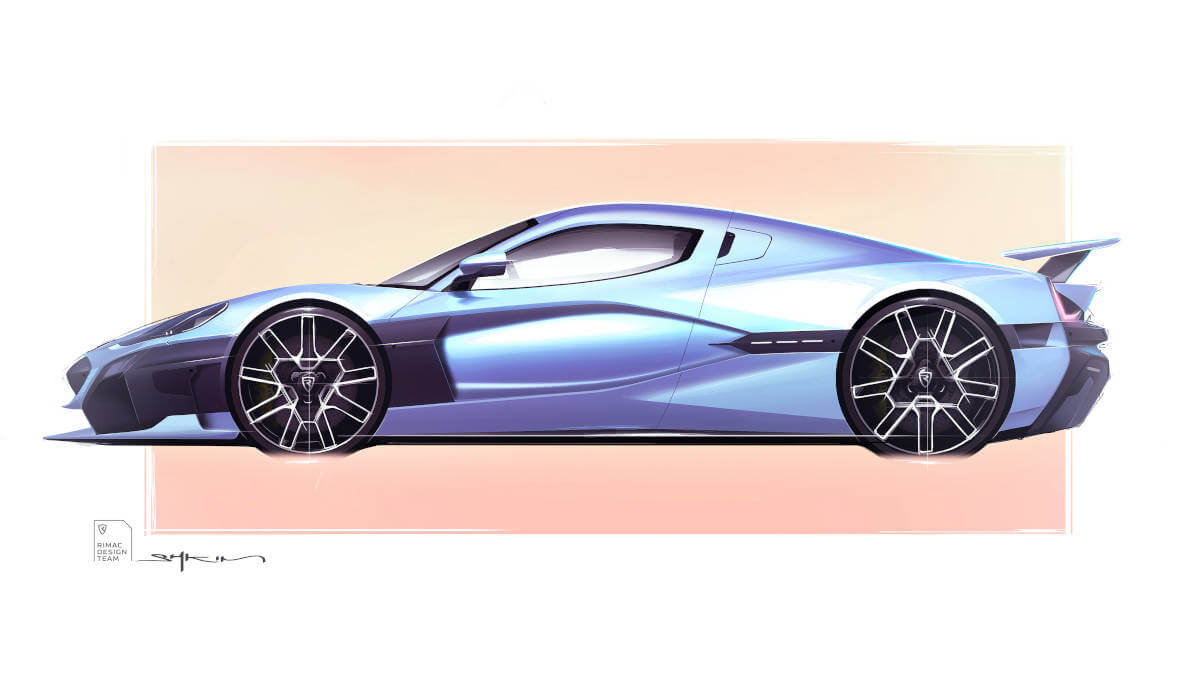

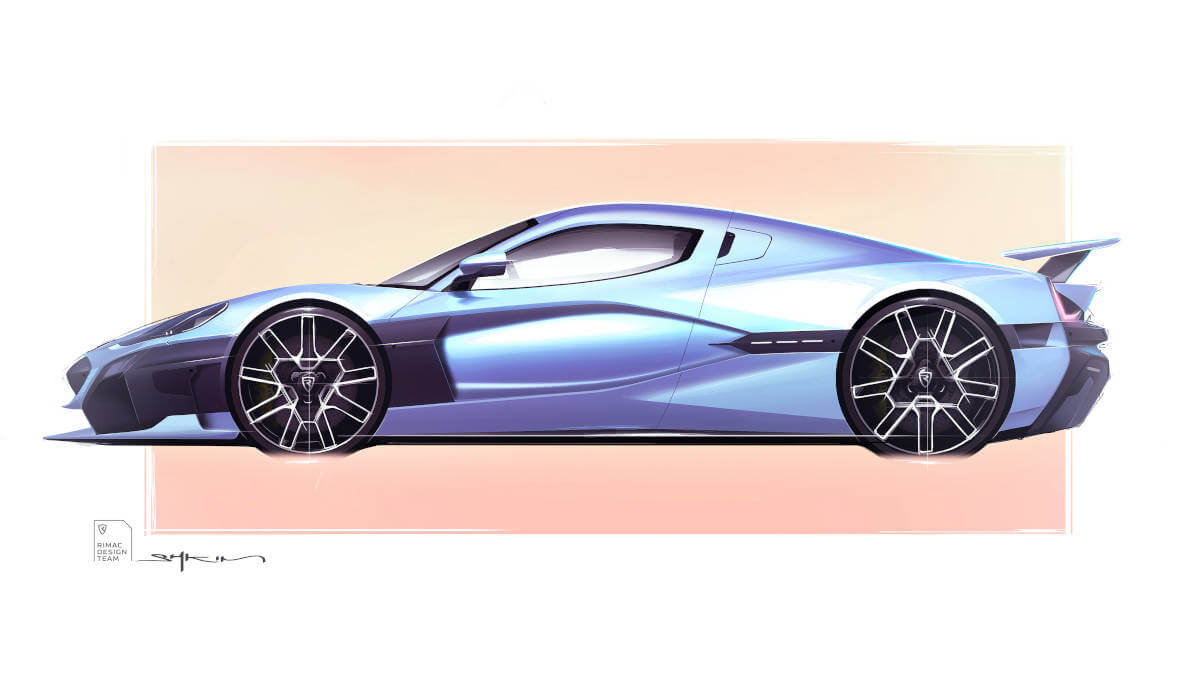

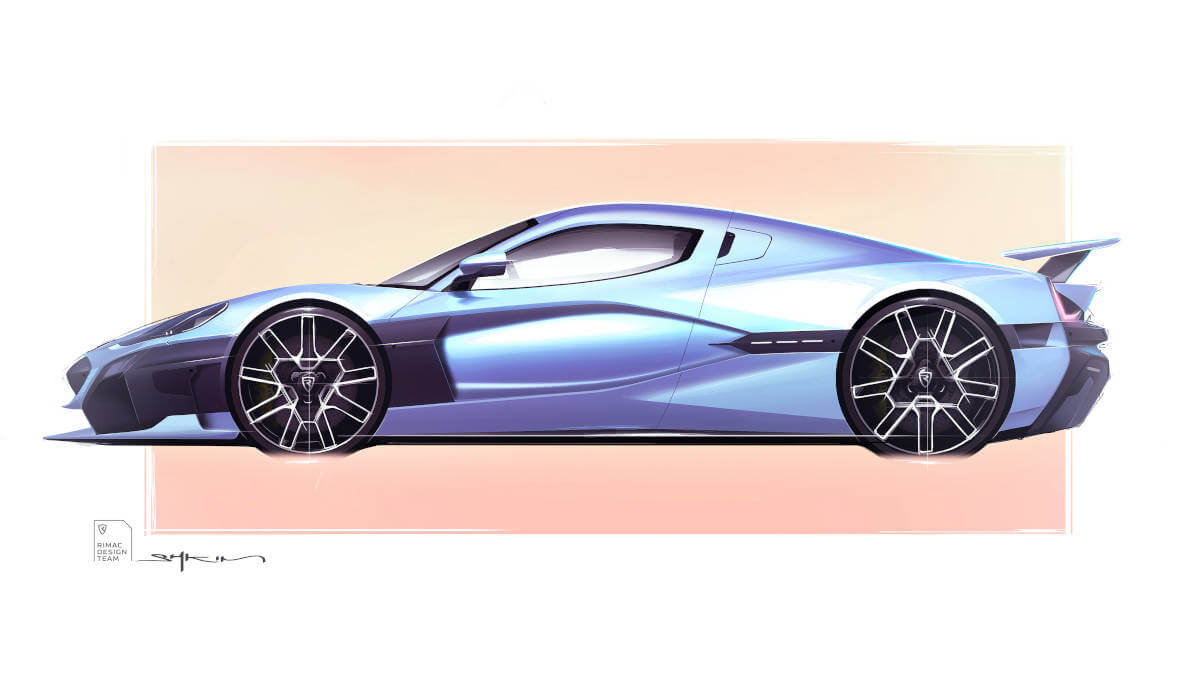

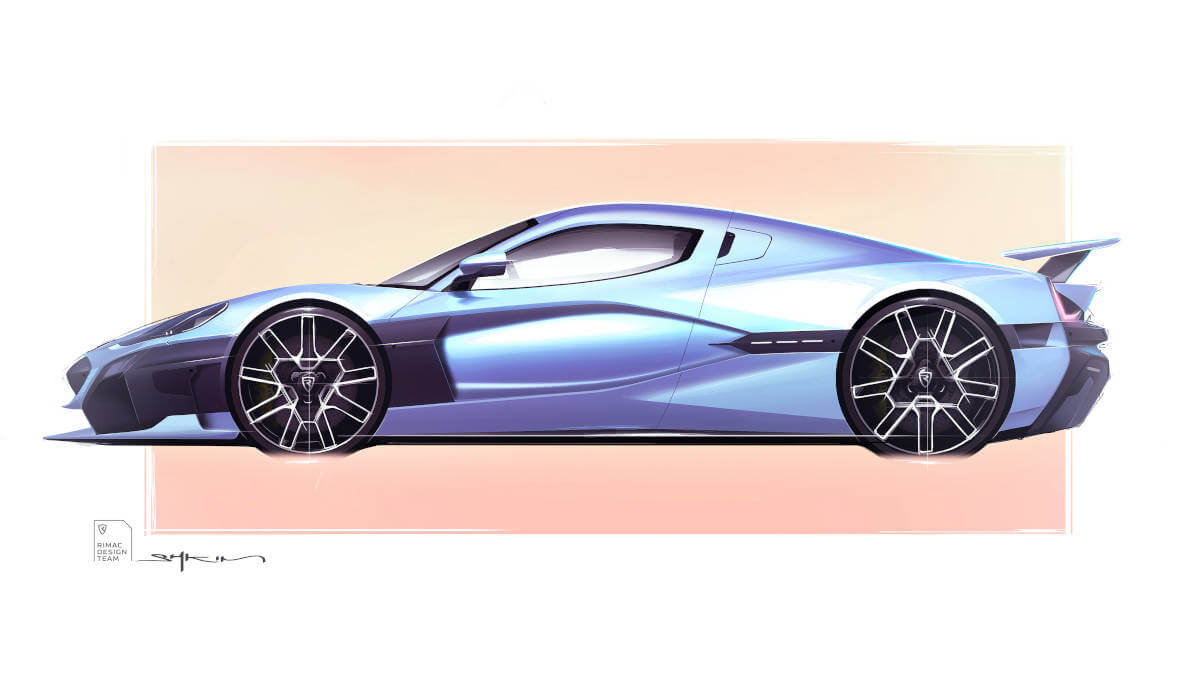

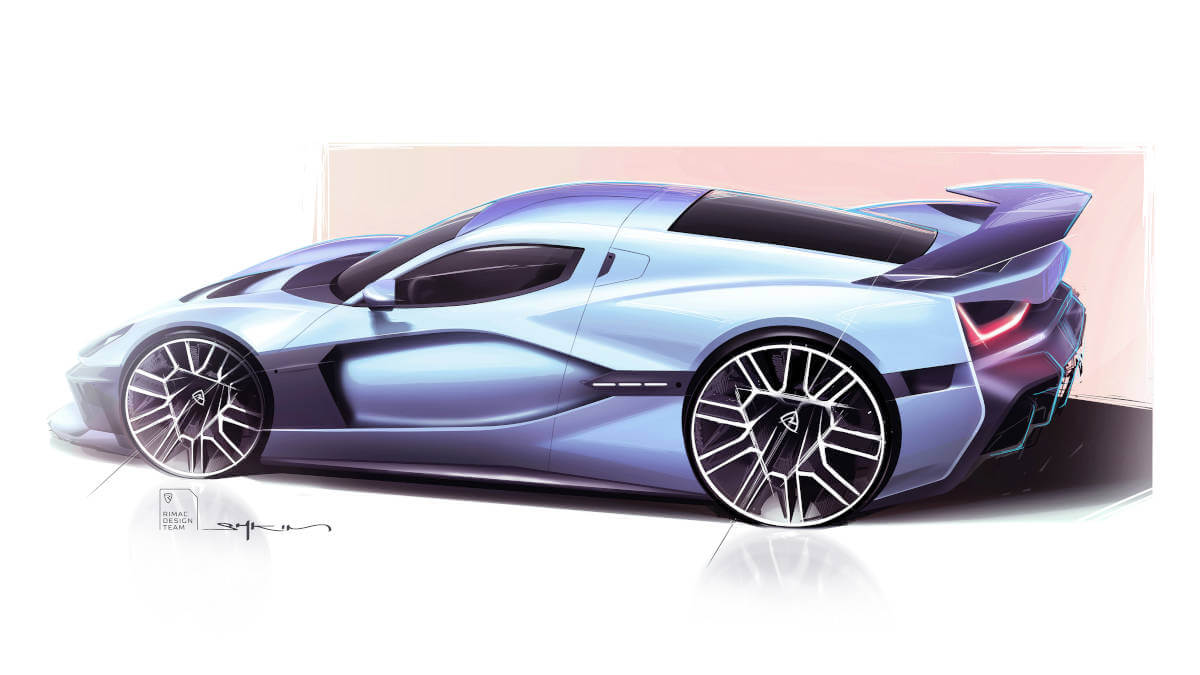

Aerodynamic refinements compared with C_Two

Visually, not much seems to have changed since the world premiere of the Rimac C_Two two years ago. However, a closer look reveals various detail improvements to the hood, roof pillars and diffuser. Rimac put the C_Two in the wind tunnel for many hours and found various small spots that could be improved on the way to the production version. So the motto “form follows function” clearly applies to the finished Rimac Nevera. Every body element helps aerodynamics, the dissipation of warm exhaust air or the cooling of the batteries. The aerodynamic efficiency of the vehicle was improved by 34 percent from the first prototype to the production car. On the flanks, the “cravat” already familiar from the Concept_One remained, a recess created behind the front wheels from a vent for the wheel arch, extending over the door and ending in a carbon clasp at the rear.

Carbon fiber body and monocoque

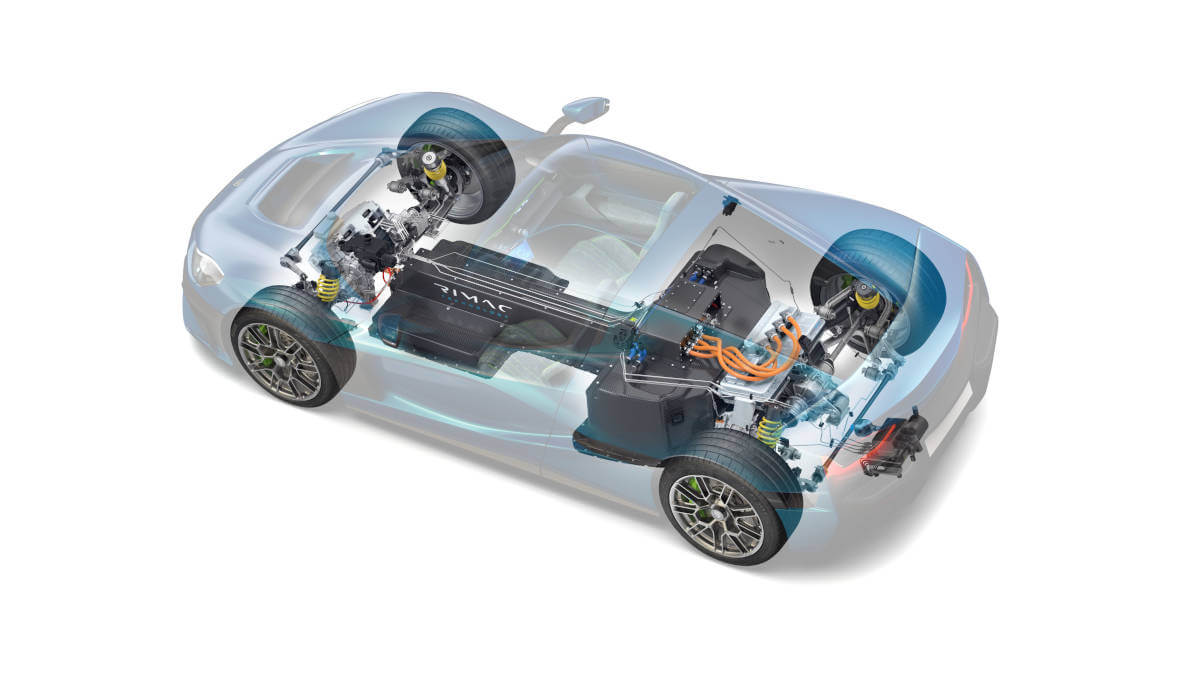

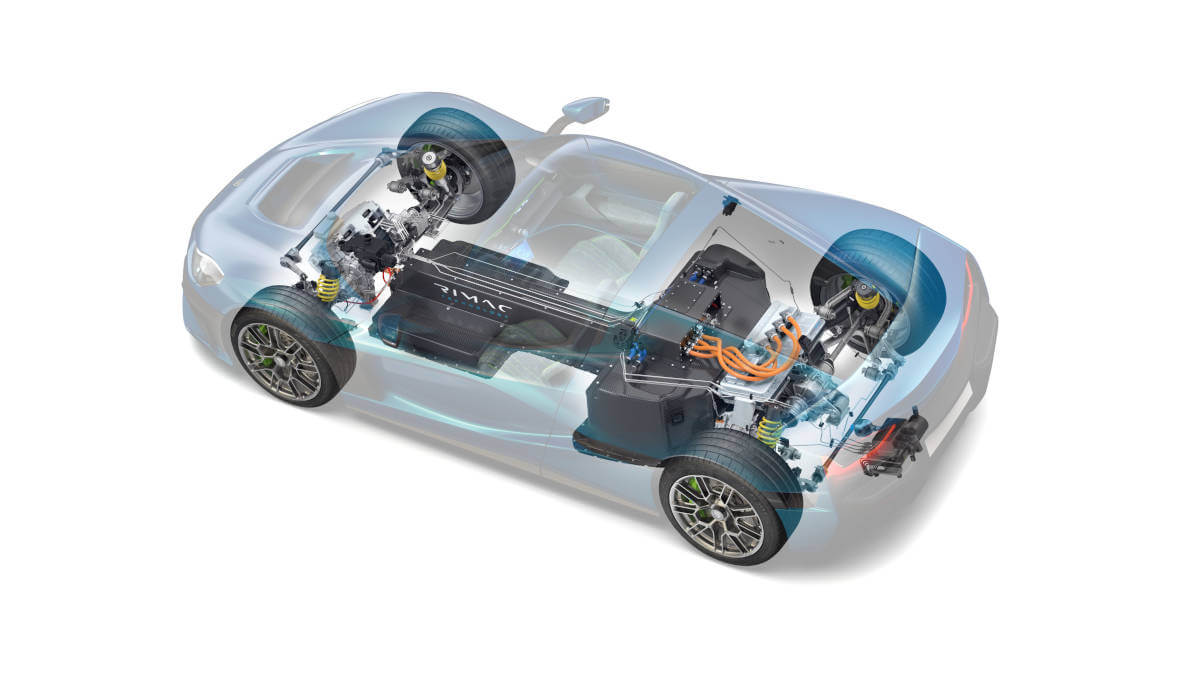

Various active aerodynamic elements were also created during the wind tunnel hours. A profile on the front hood, flaps on the underbody, diffuser elements and the rear wing position themselves optimally in the airstream depending on the driving situation. The forged alloy wheels also received a new design to direct more cooling air to the carbon-ceramic brake system from Brembo. Under the carbon body is a carbon monocoque developed by the former chief designer of the C_Two with an integrated roof, battery compartment in the floor and rear subframe. This monocoque weighs less than 200 kilograms and is the largest single carbon component in the automotive industry.

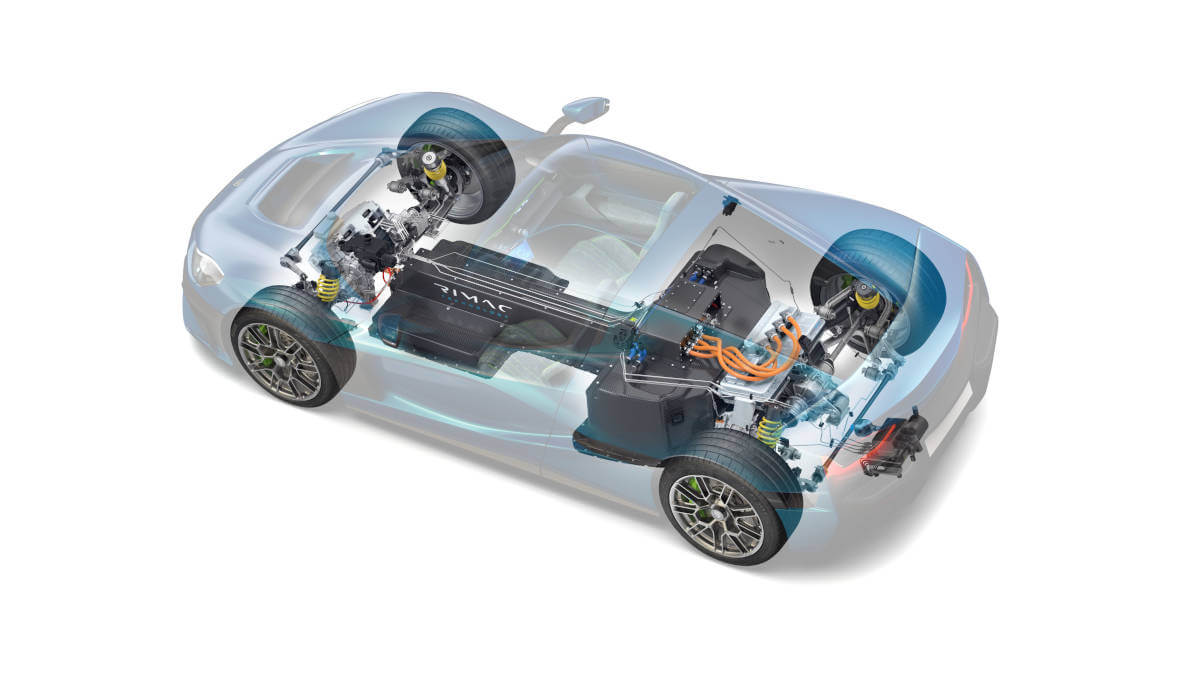

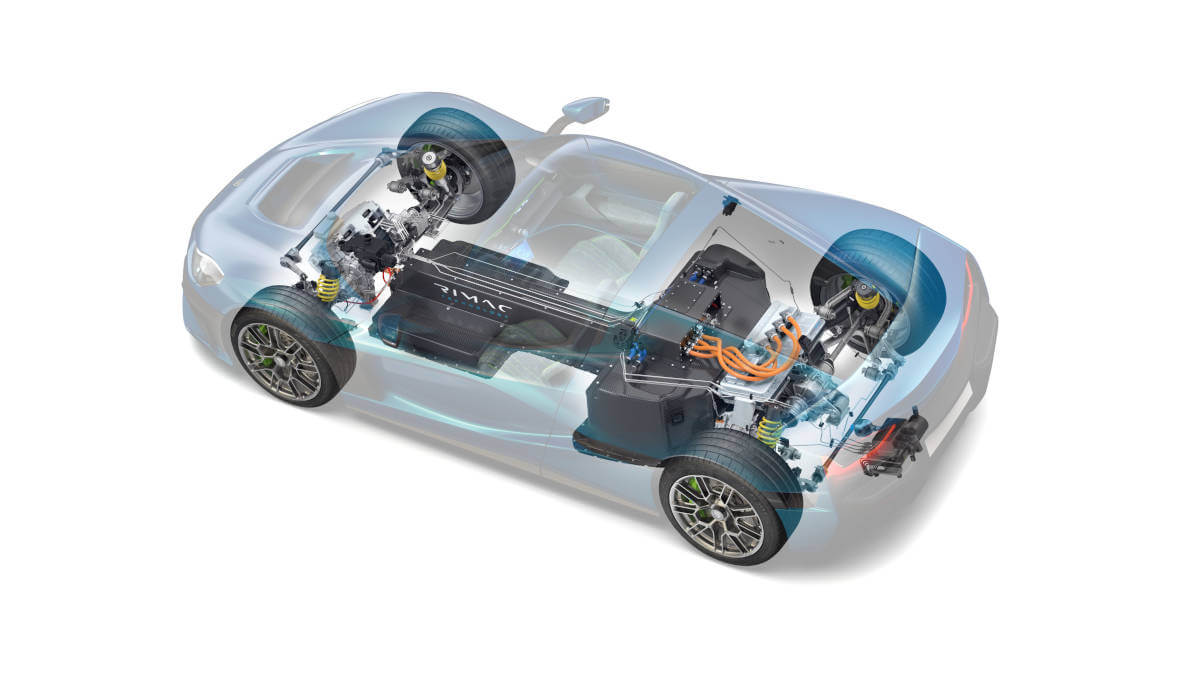

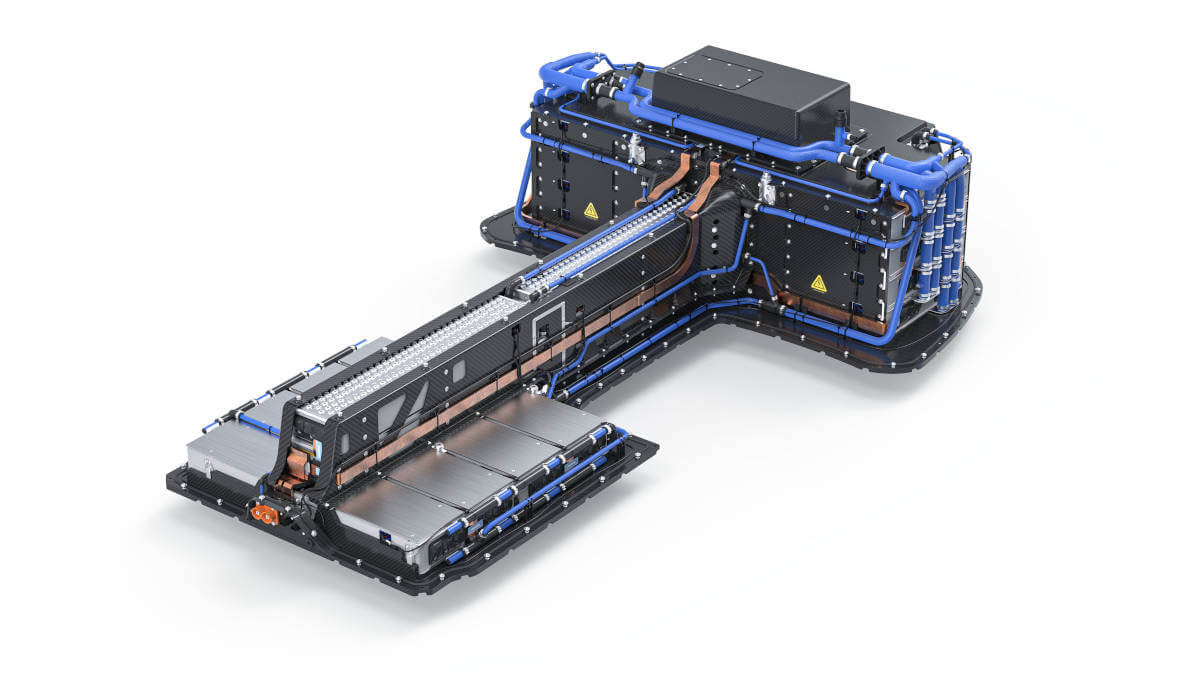

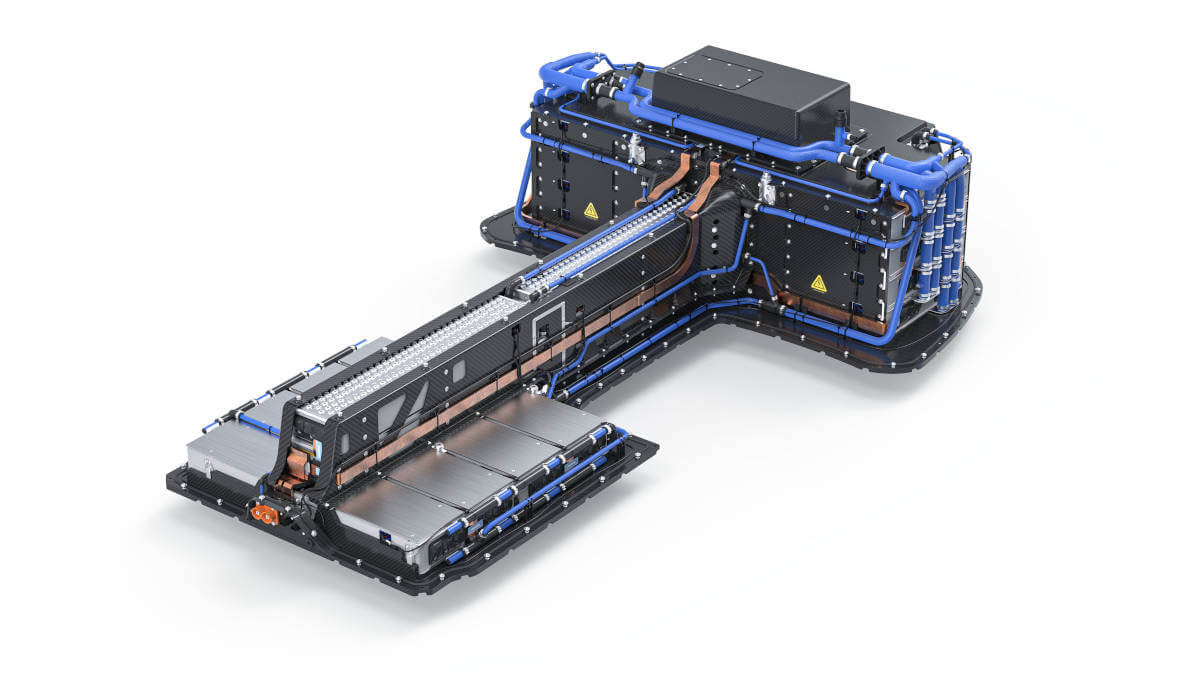

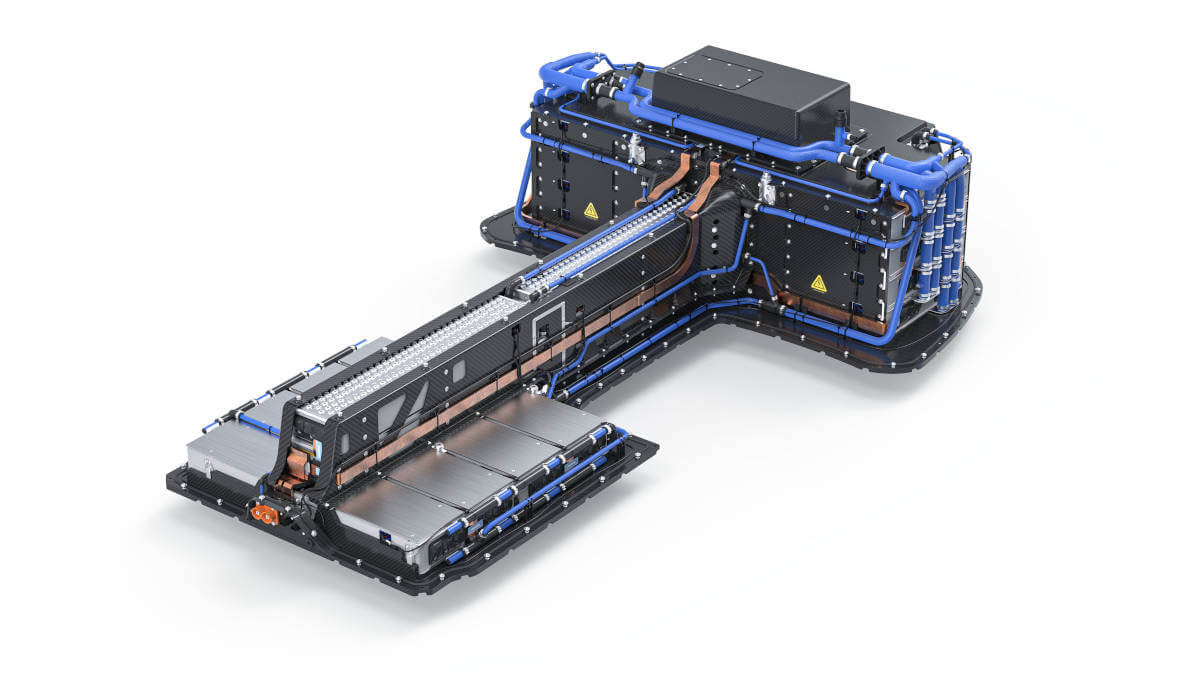

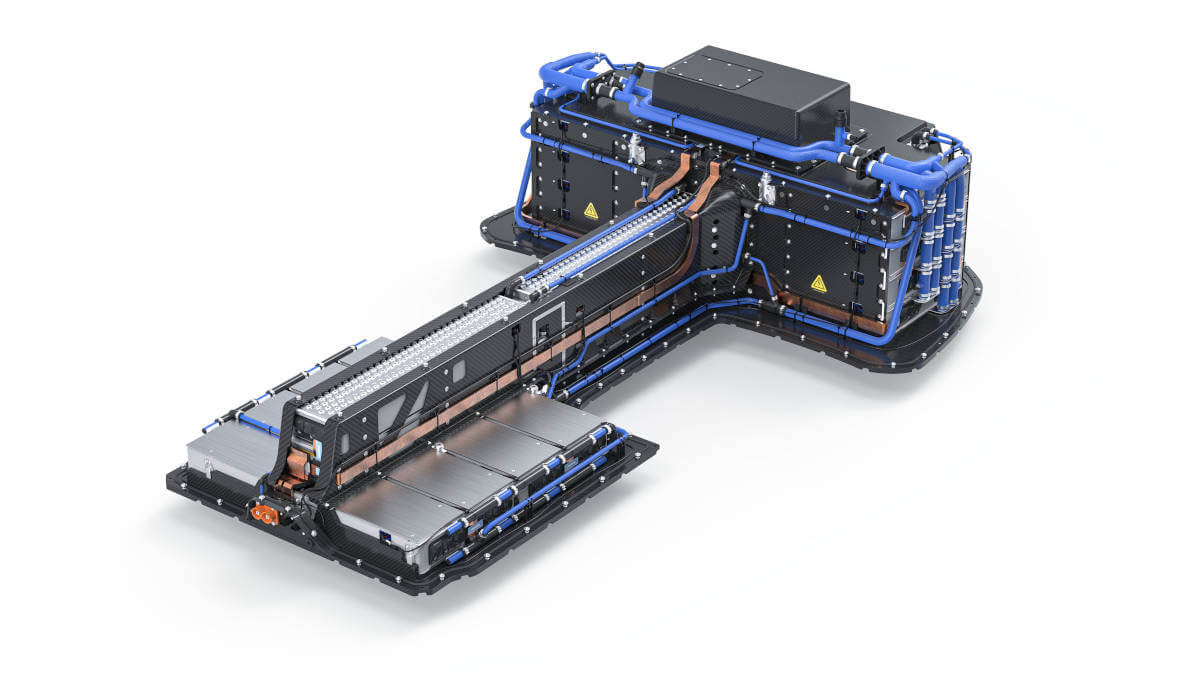

120 kWh lithium manganese nickel battery pack

Rimac is one of only a few automakers that develops and manufactures its own electric drive technology. This service is also offered to external companies, which is why the battery technology in the Aston Martin Valkyrie and Koenigsegg Regera comes from Rimac. The new Nevera is fitted with a liquid-cooled lithium-manganese-nickel H-shaped battery pack with 6,960 cells and 120 kWh. This is designed in such a way that it alone provides 37 percent of the vehicle’s rigidity. It also plays a key role in the 48:52 weight distribution between front and rear. Instead of traction control and ESP, Rimac uses R-AWTV 2, the second generation of its proprietary torque vectoring system between all four wheels. More than 100 calculations per second are made by the sensors to ensure that the torque is applied to the road in the right way.

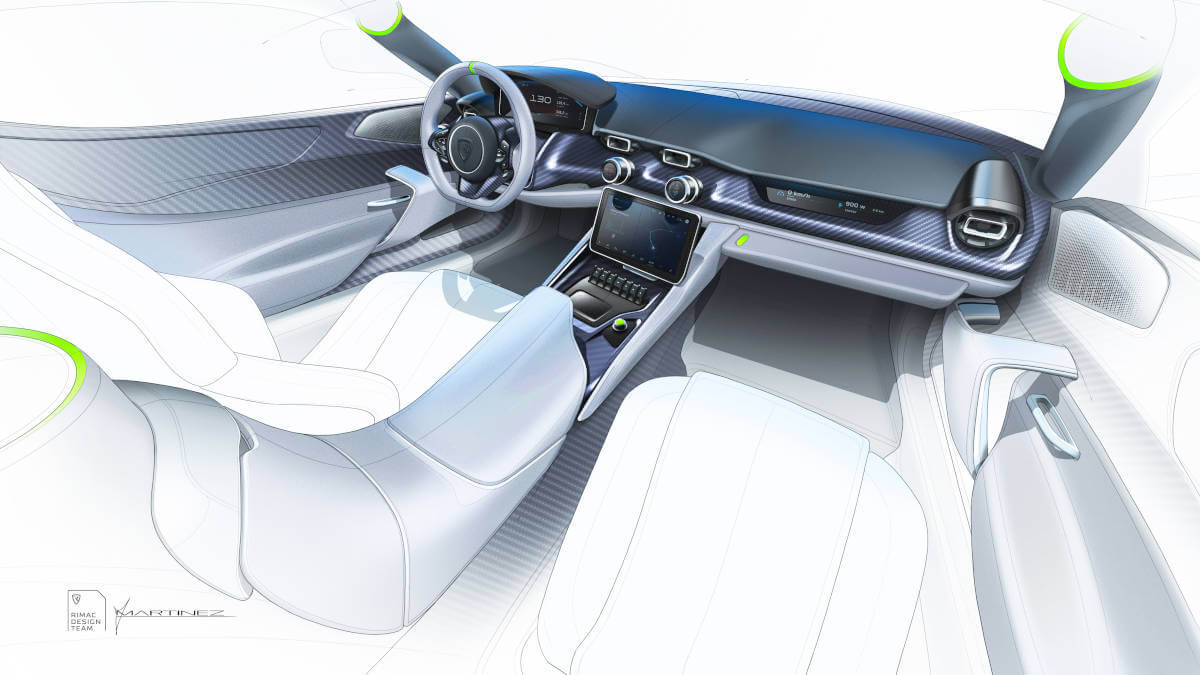

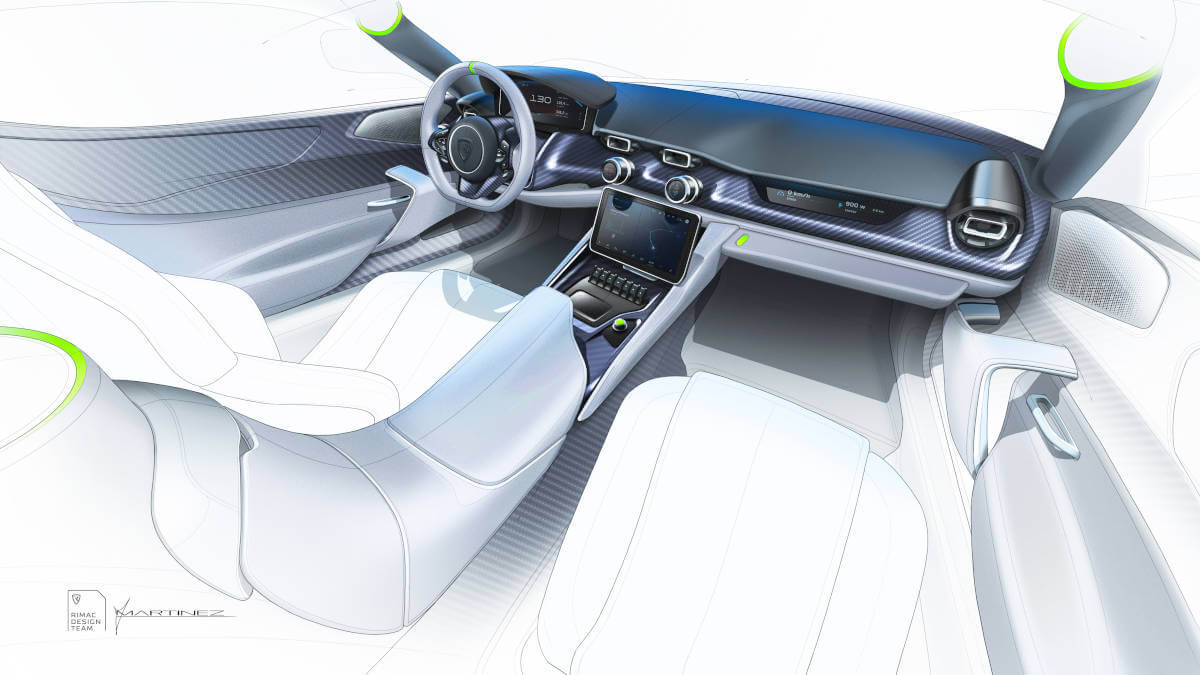

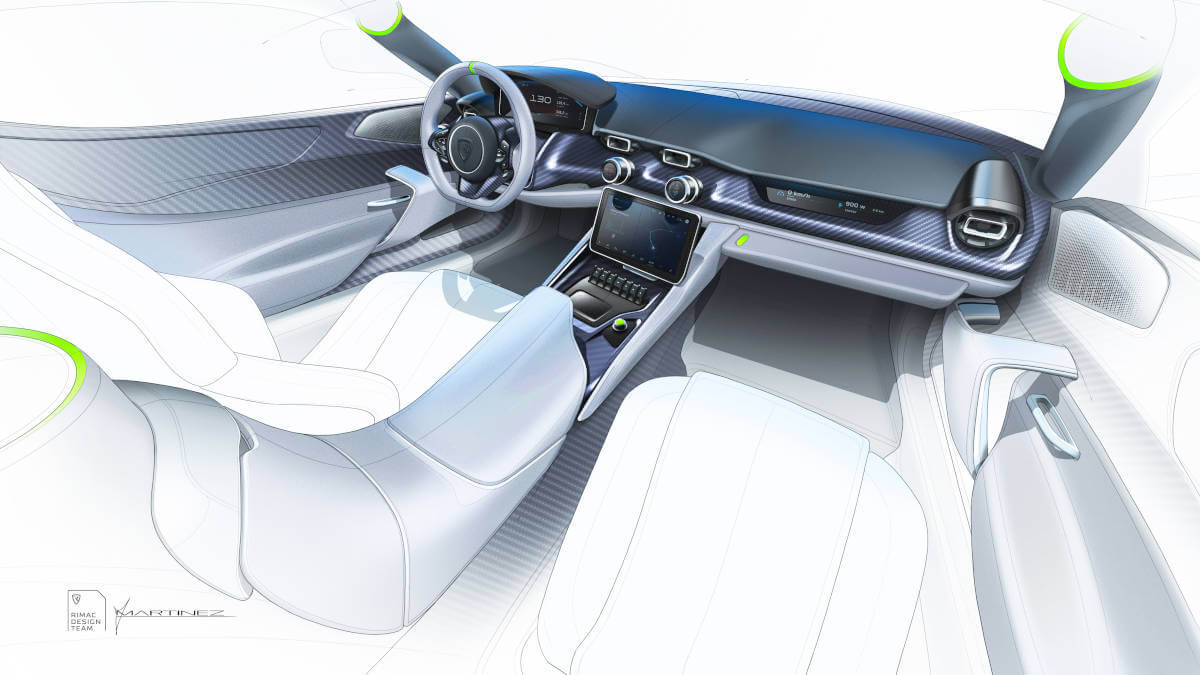

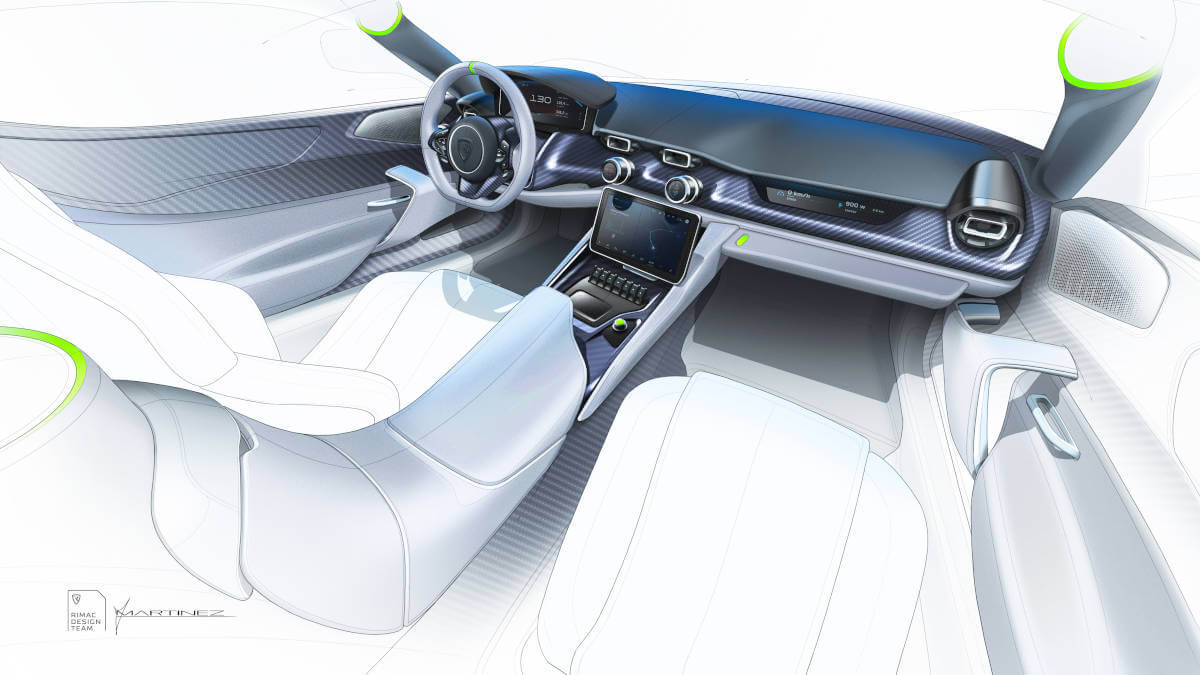

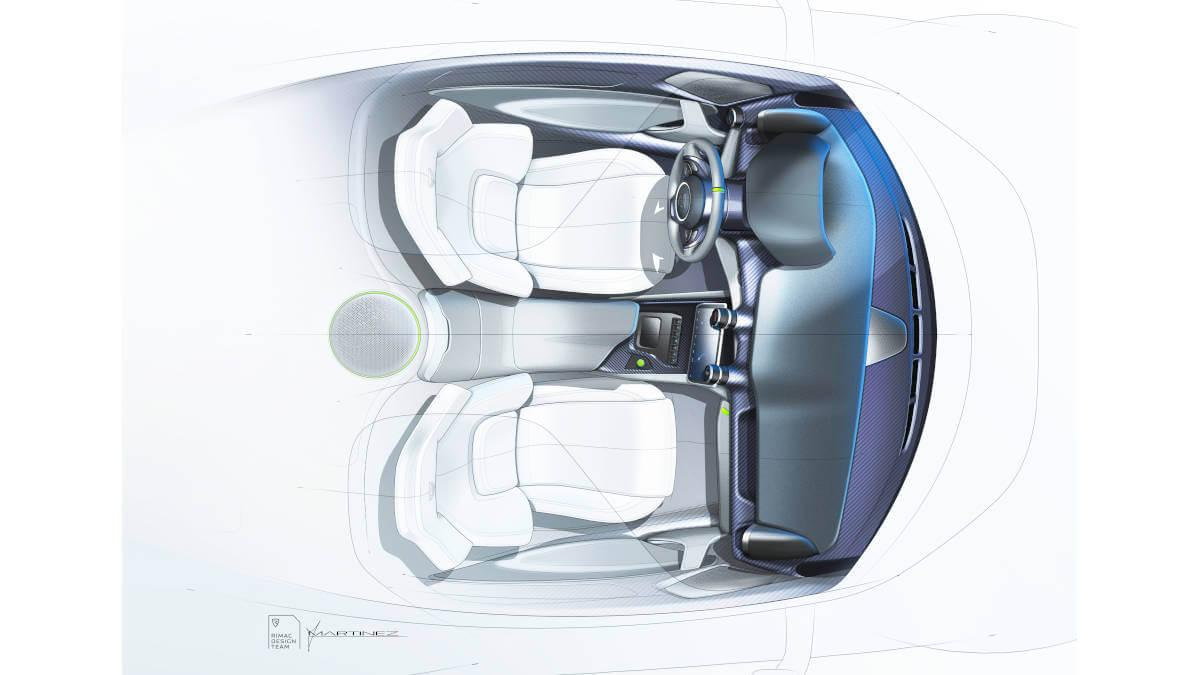

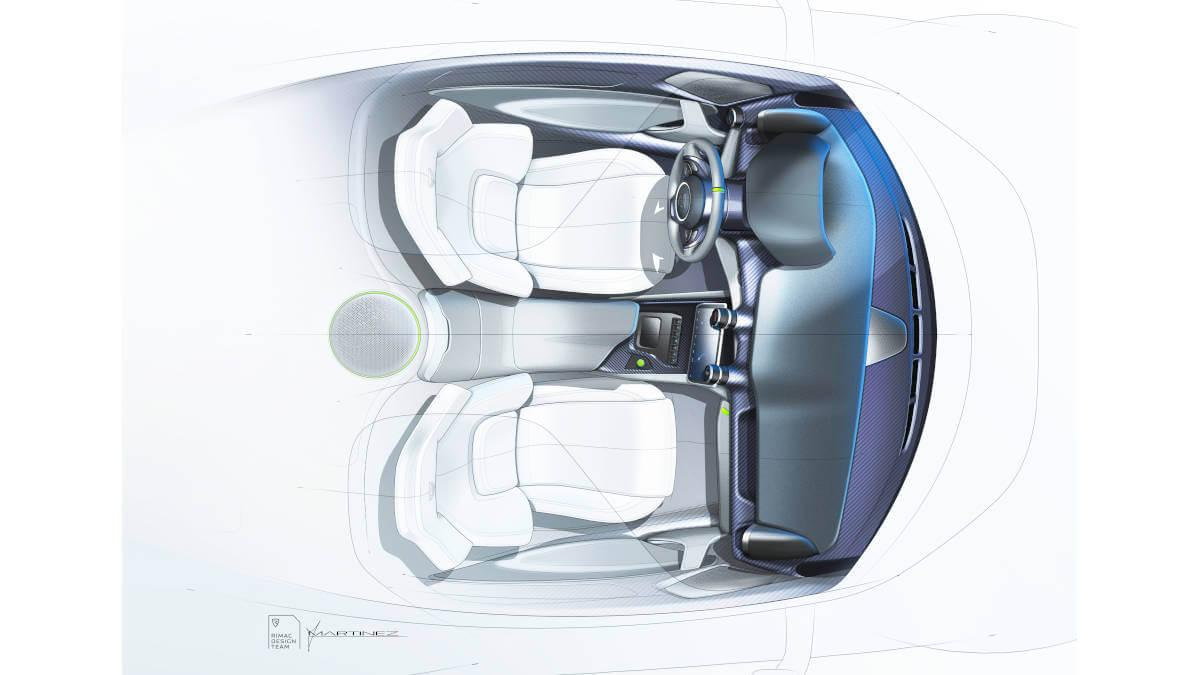

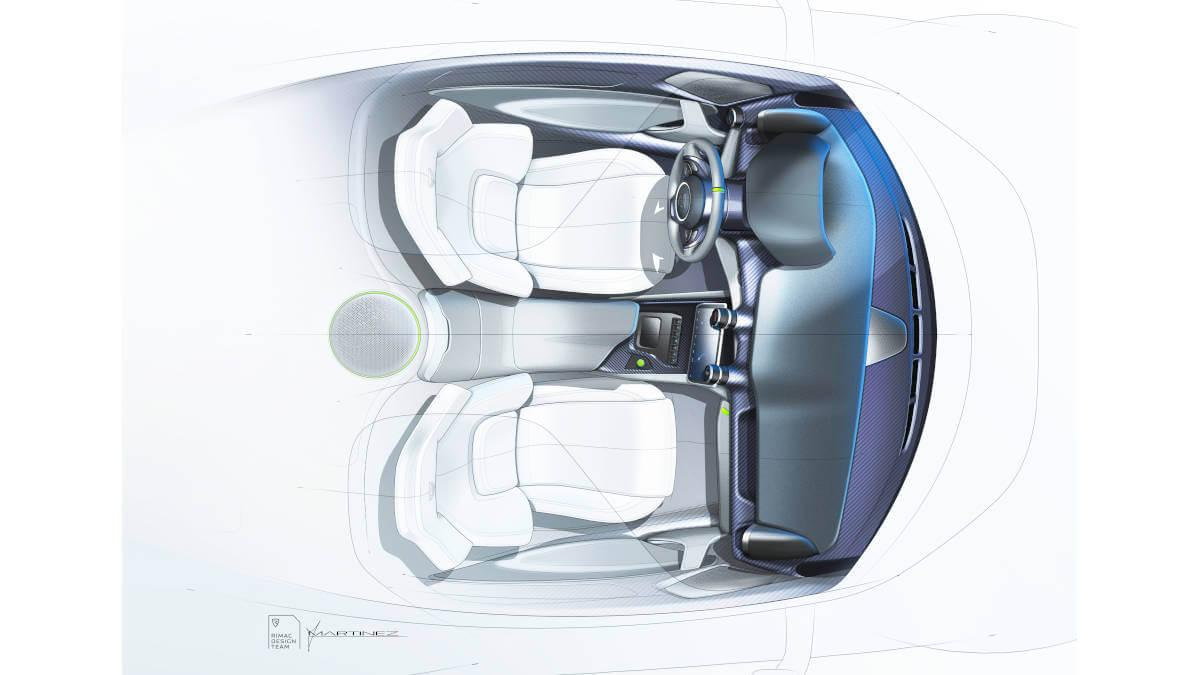

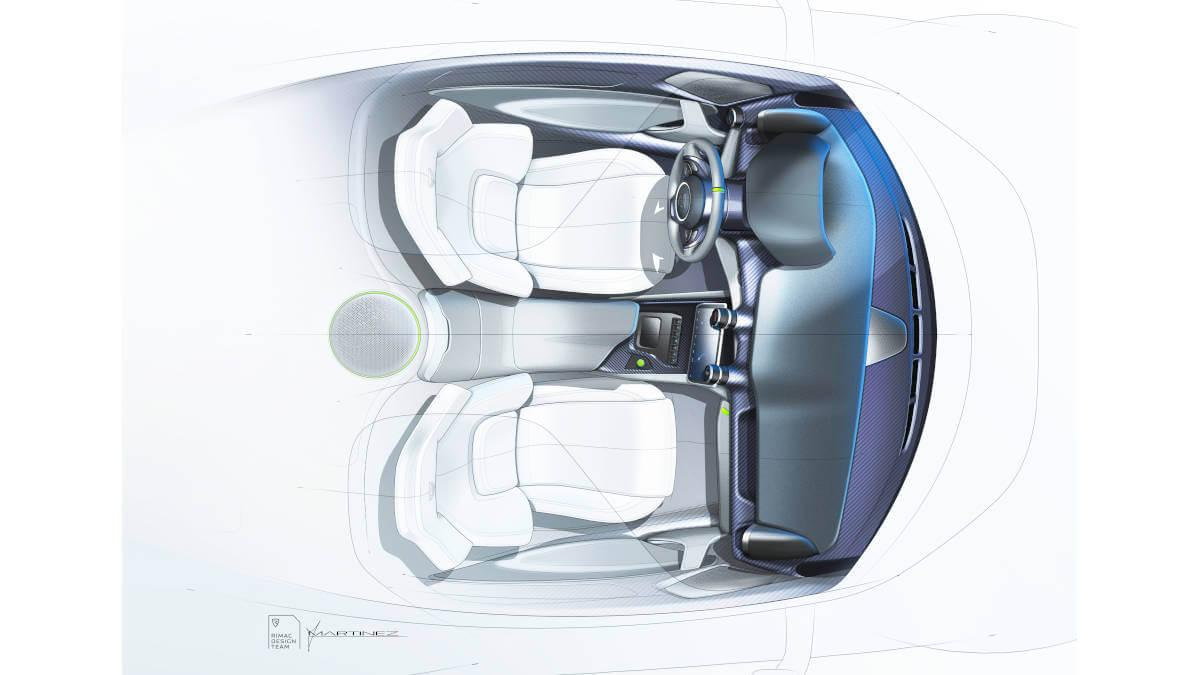

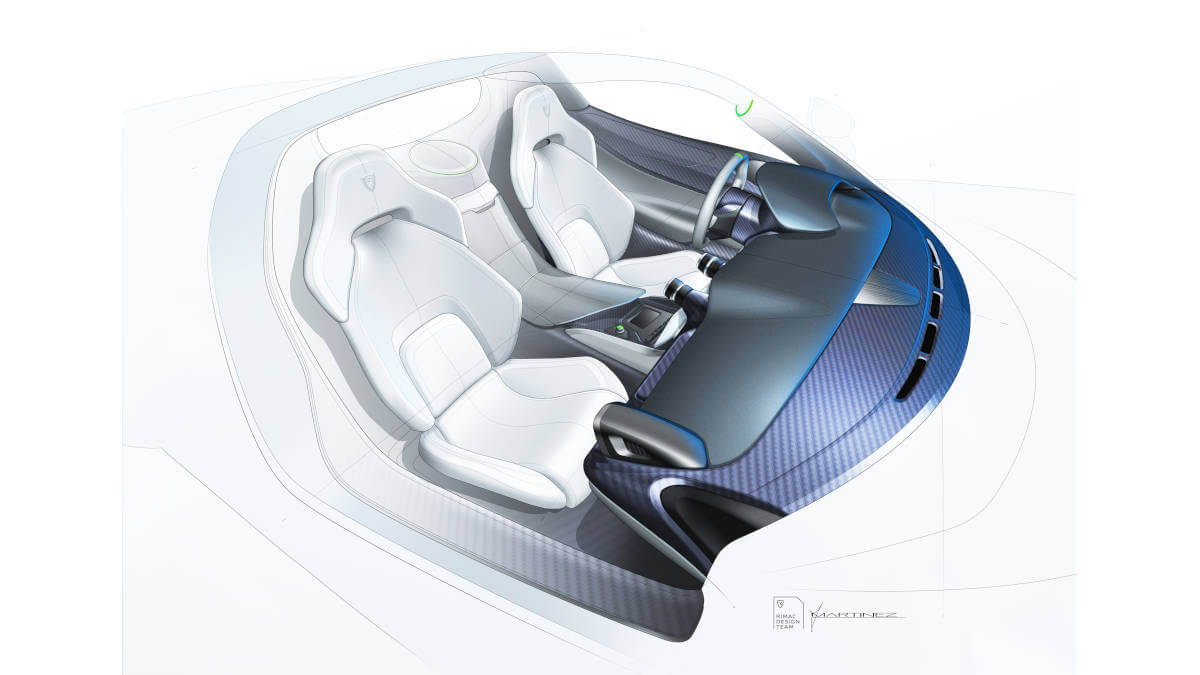

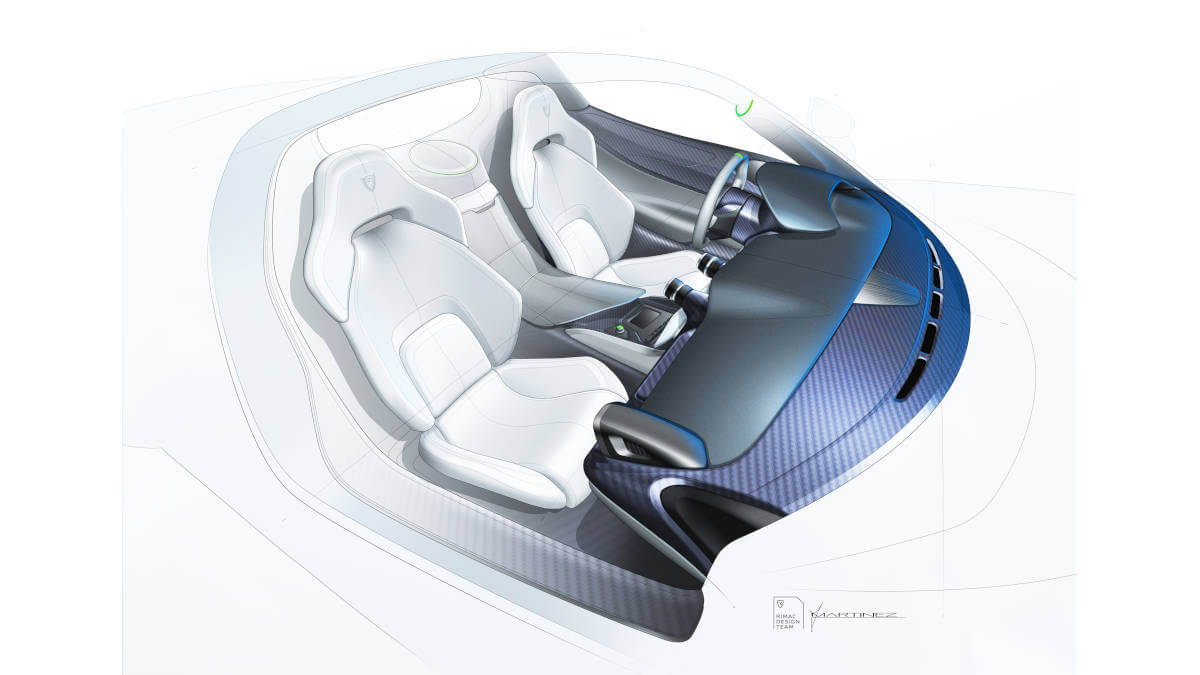

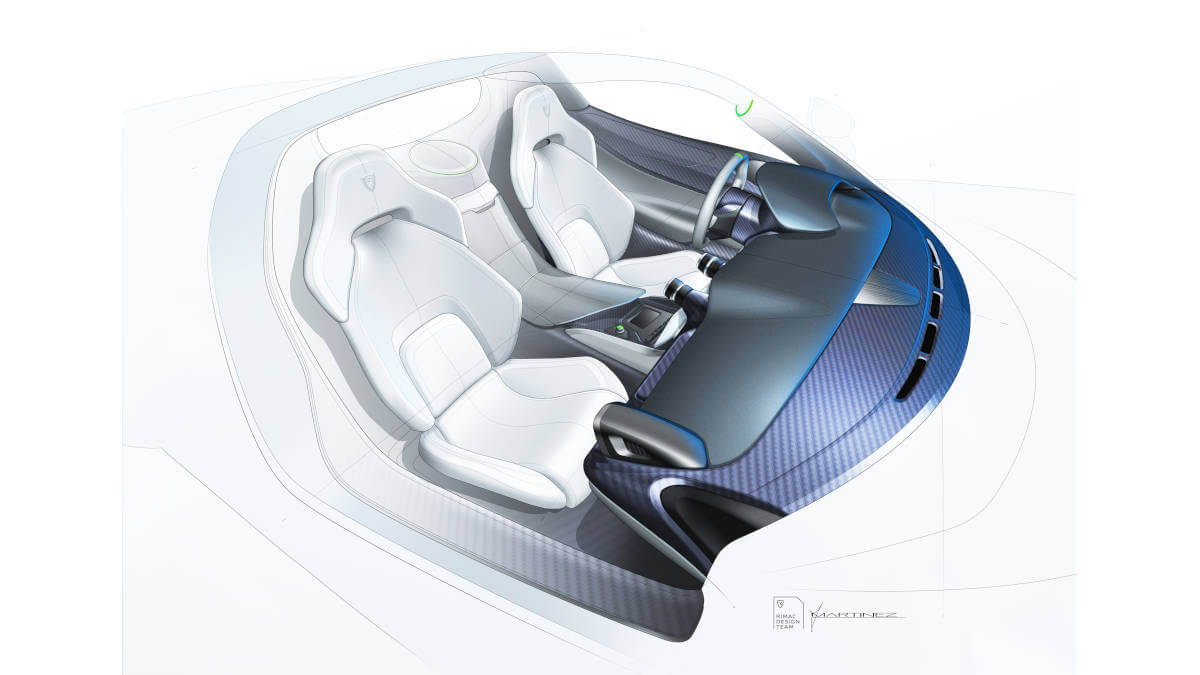

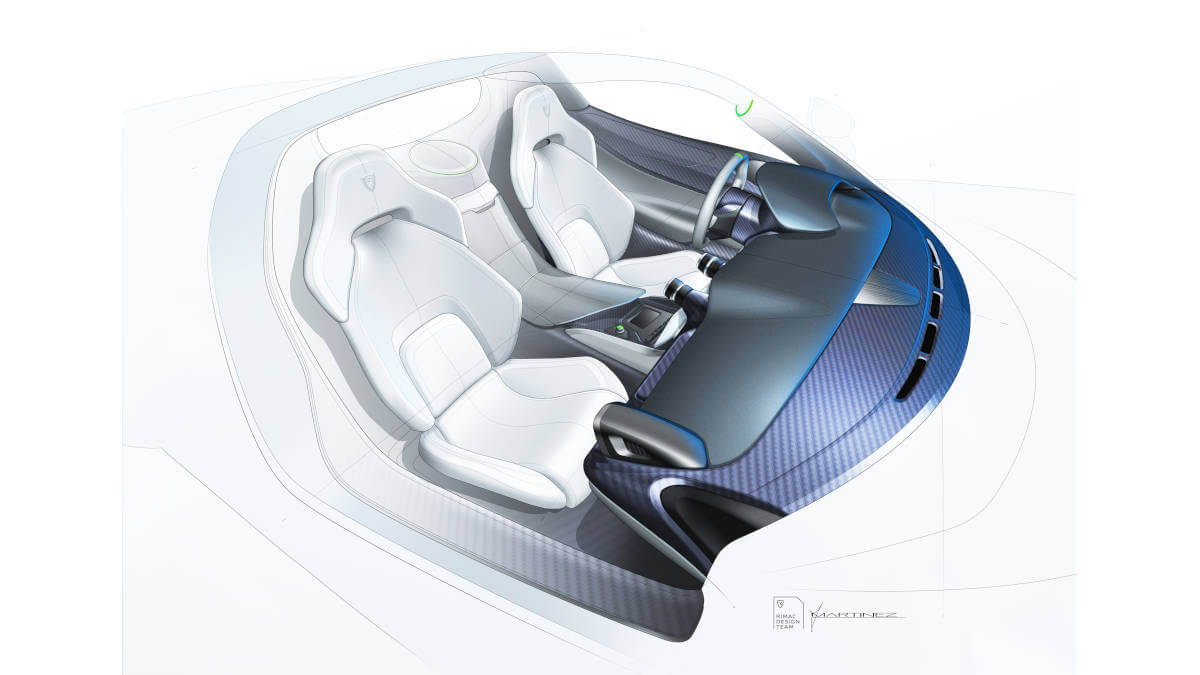

Ample power for two million euros

For two million euros apiece, customers now get a 1,408 kW/1,914 hp vehicle with a topspeed of 415 kph (258 mph). The maximum torque on the data sheet is 2,360 Nm. The four permanent magnet motors drive the wheels directly. According to the official data sheet, the car accelerates to 62 mph in 1.85 seconds and to 186 mph in 9.3 seconds. Thus, the car is 2.5 seconds faster to 186 mph than originally targeted. Rimac plans to produce a total of 150 units. Customers can choose from a variety of individualization options for the color scheme of the exterior and interior.

Images: Rimac Automobili