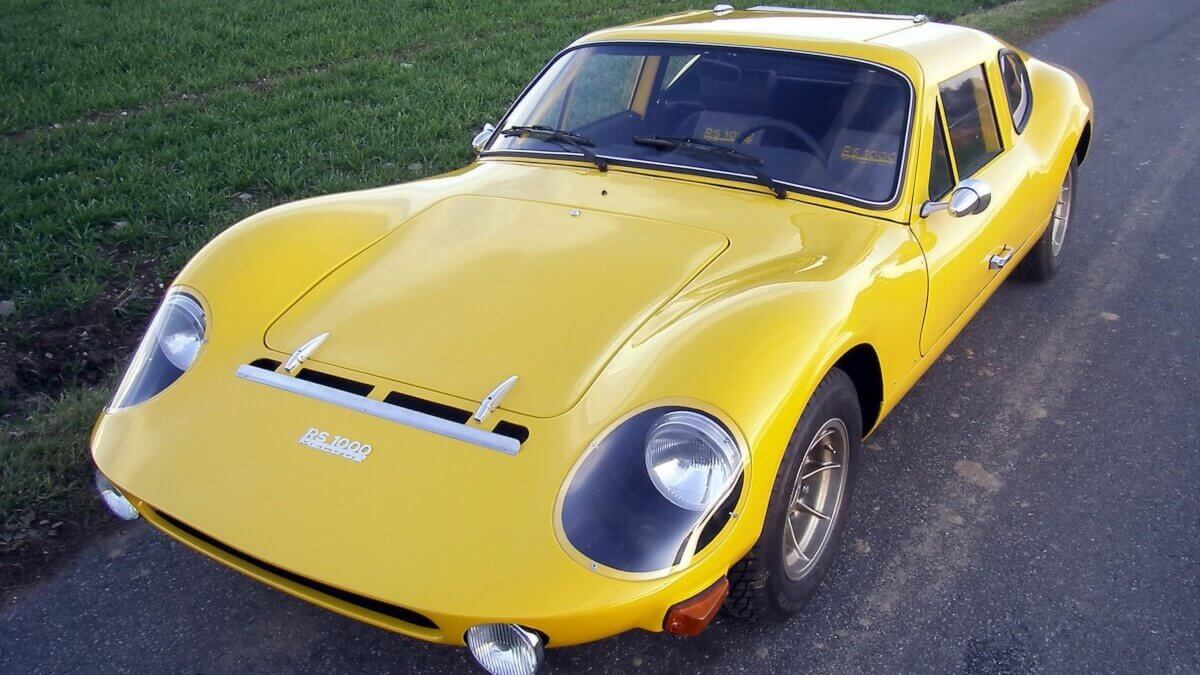

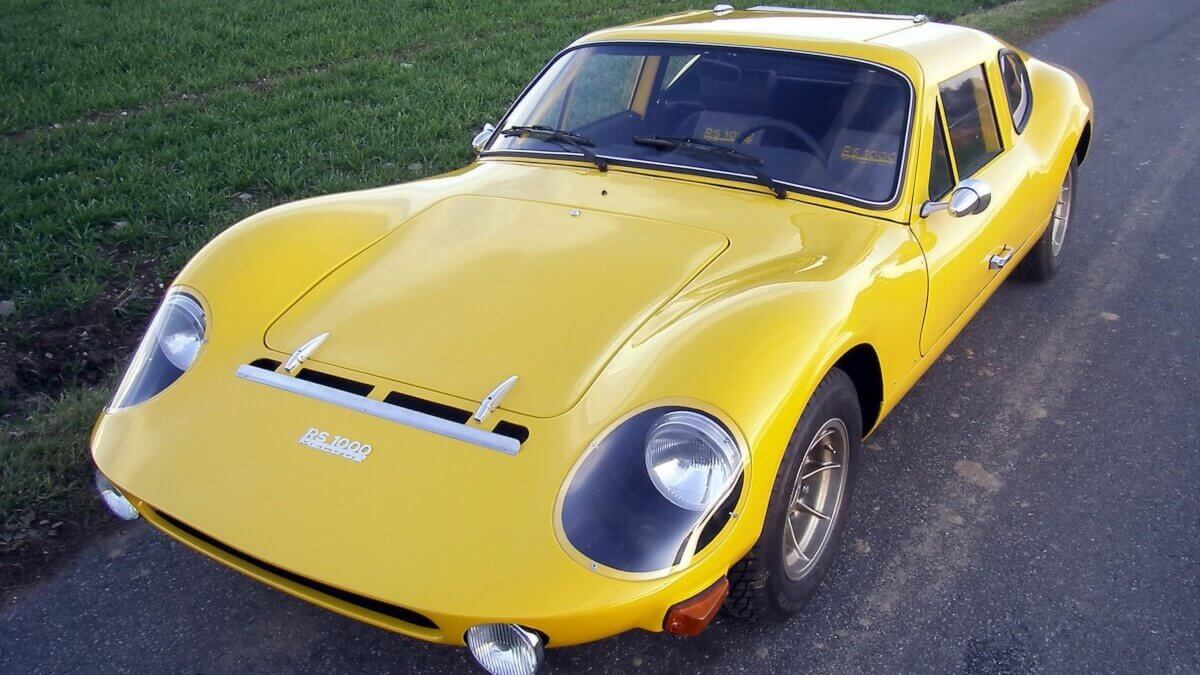

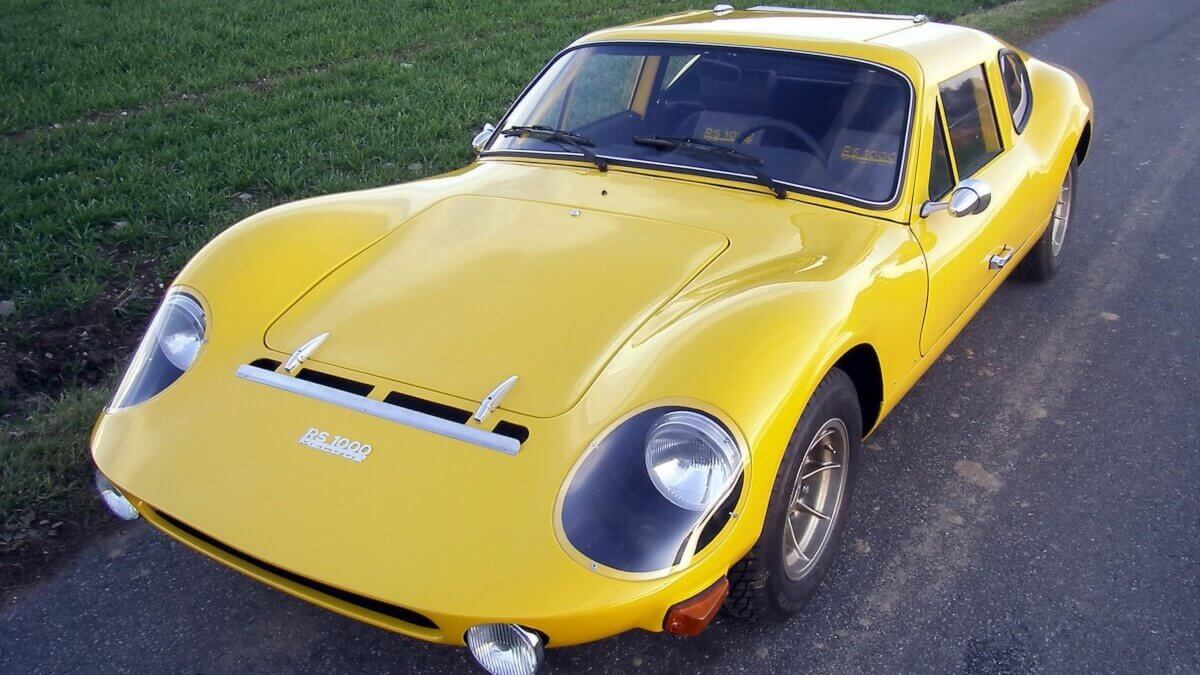

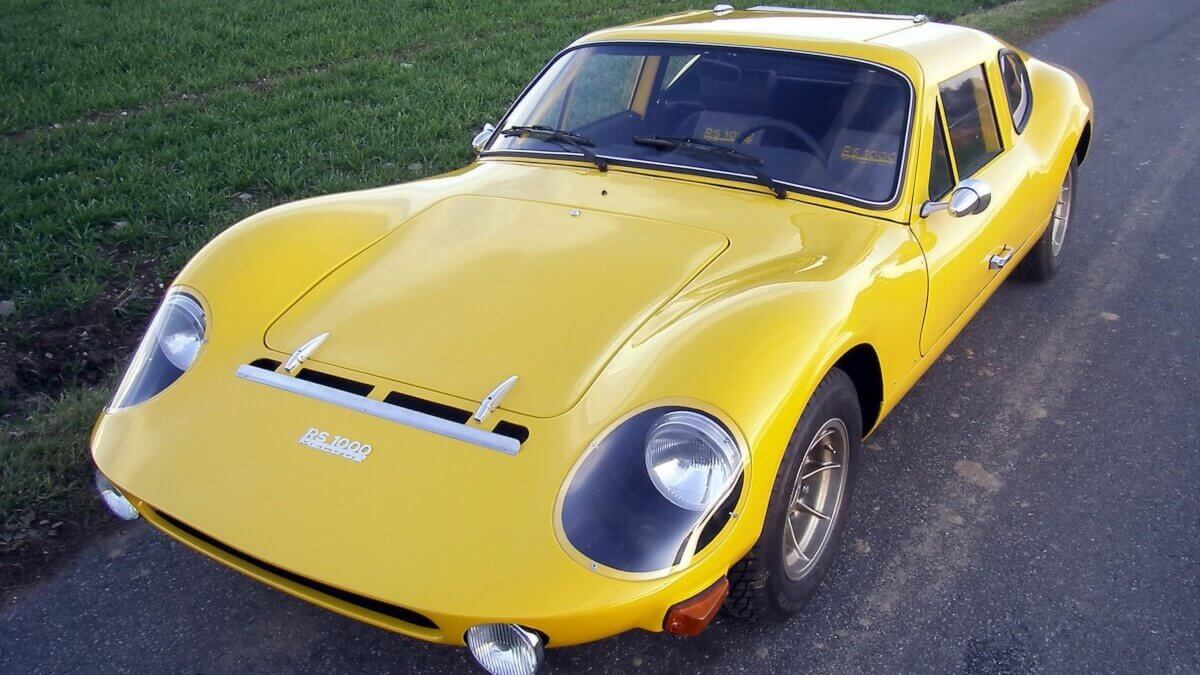

50 Years of Melkus RS1000

The automotive scene of the former German Democratic Republic (GDR) was far from being as democratic as the state name promised. From the government came clear instructions to the only two licensed car manufacturers Sachsenring and Wartburg. Changes and modifications to the existing constructions took years or decades or were prohibited at all. New developments were rare and although various projects were done, most of them ended in car depots or on paper without ever reaching prototype state. In addition to the Trabant P601 and the Wartburg 353, there were no other vehicles from local production in the mid-1960s. Even from the socialistic states around, like the Soviet Union or Czechoslovakia, there was only a limited selection of cars, which often weren’t easily available for GDR citizens. Those, who dreamed about racing cars in motorsport or to own a sporty vehicle often only got the answer: “Nyet!”

The only way to enjoy a sporty automobile was to buy components and available spare parts and built one in the garage. But this ‘availability’ was much more limited than today, with full spare parts warehouses and the possibility to order them online and get delivery within 24 hours. Heinz Melkus from Dresden was one who lived the motorsport dream. From 1955 he started in international sportscar and formula racing events, but was mostly inferior with his old material compared to the big teams. When the new Formula Junior was announced for 1958, he wanted to be competitive from the start, but needed a bit of support from the government. There, in the GDR government, they wanted to stop people to start in international car races, as previous efforts often ended far behind expectations. High diplomatic skill, the use of his network and some well-worded publications, Heinz Melkus achieved a change to the opinion that street car racing is “a socially important, useful and necessary activity”. In this way he received the important quota commitments for parts and components, without which nothing worked in the planned economy of the GDR. From these parts he together with other enthusiasts developed the first East German Formula Junior race car with two-stroke engine, which scored some good places in international racing. With the construction of the Berlin Wall and the closing of the western borders in 1961, free participation in big European races suddenly stopped.

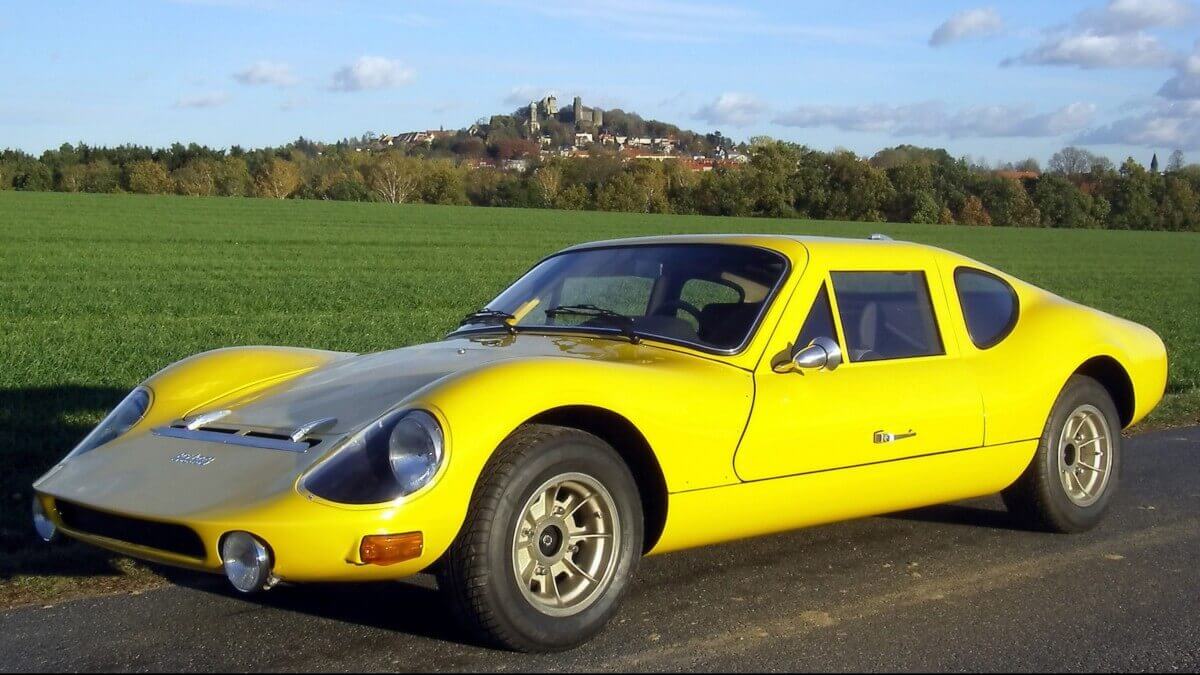

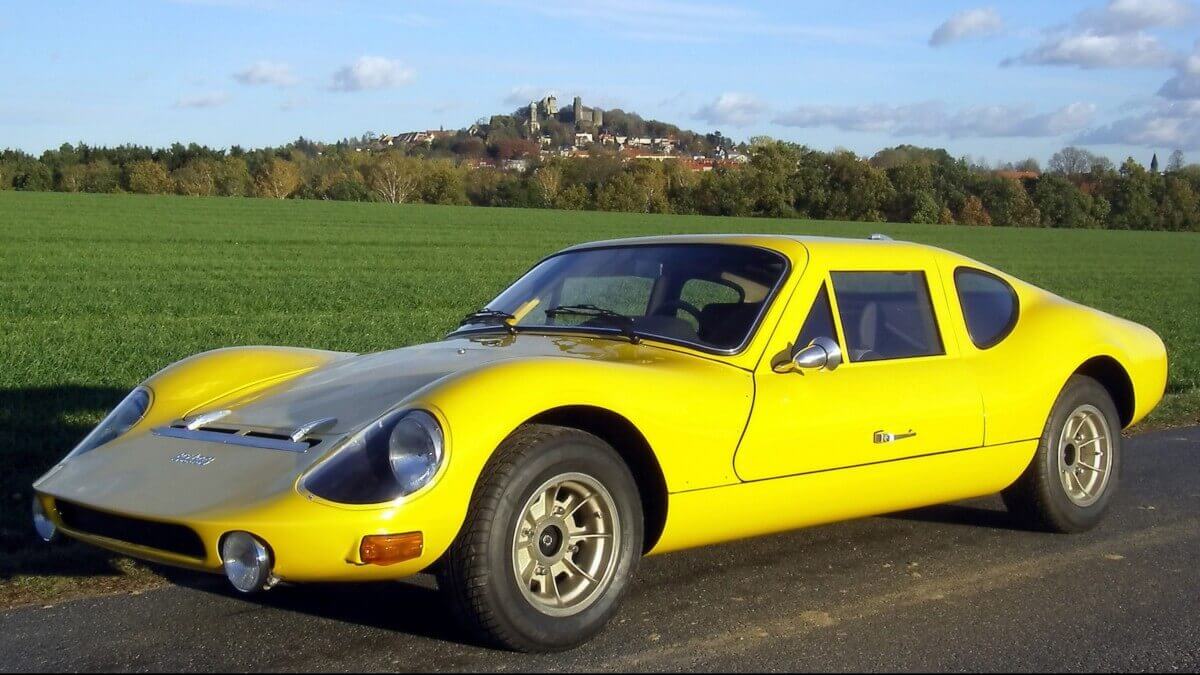

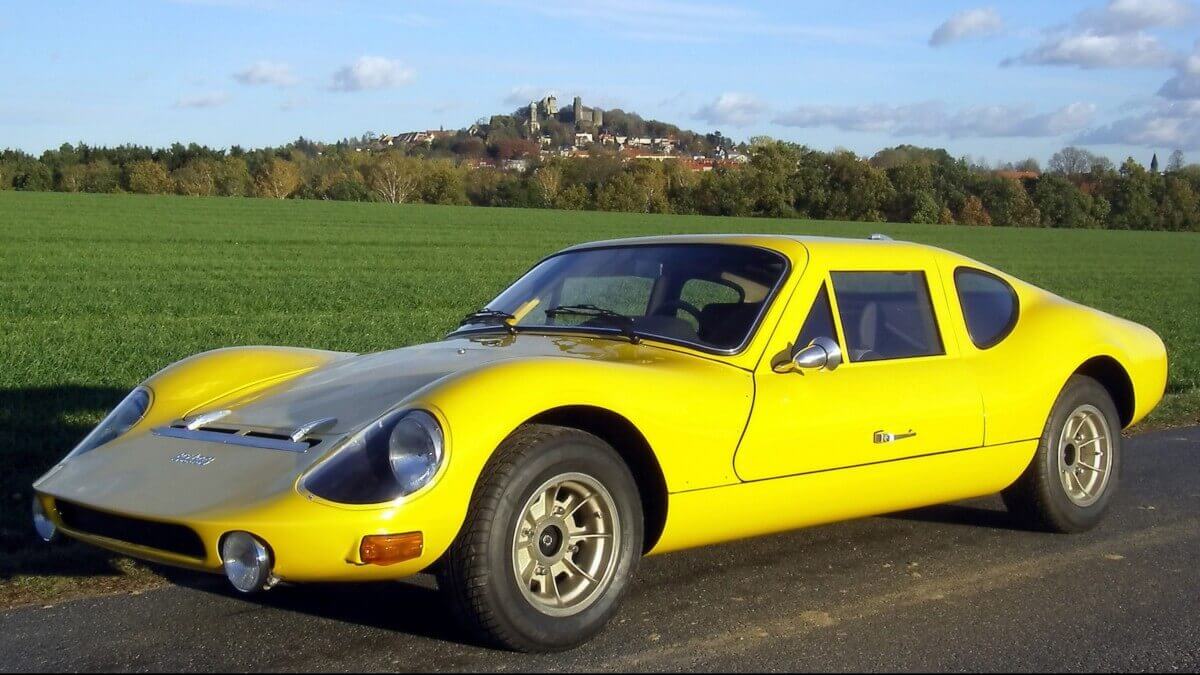

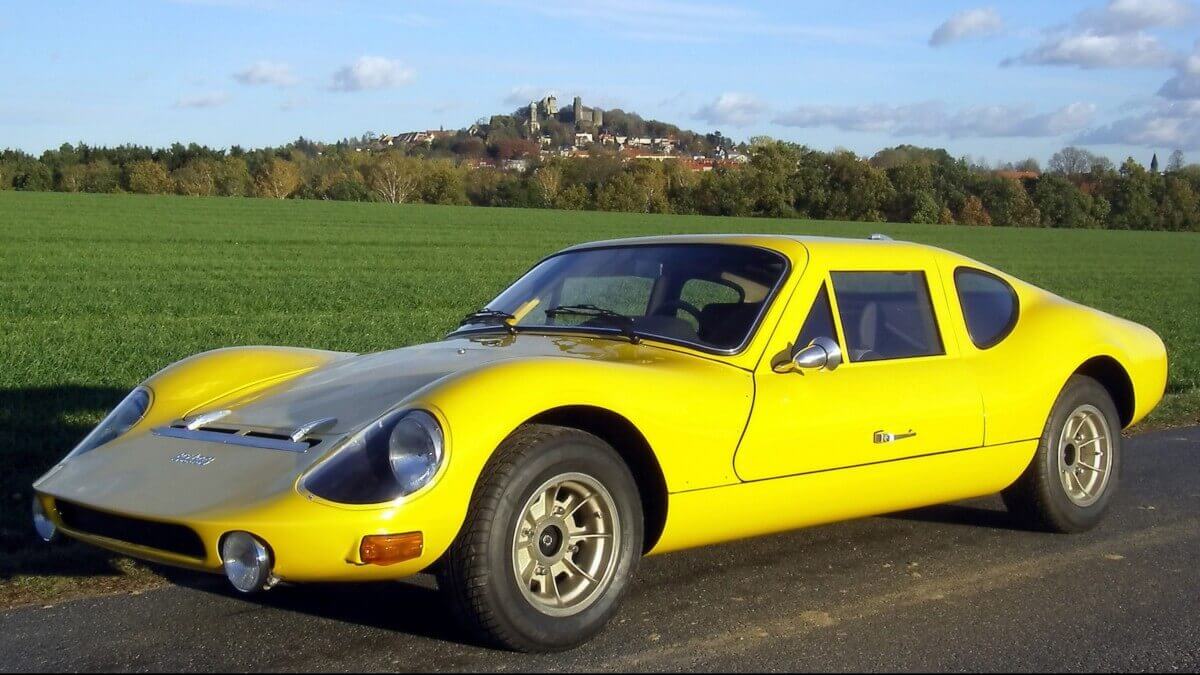

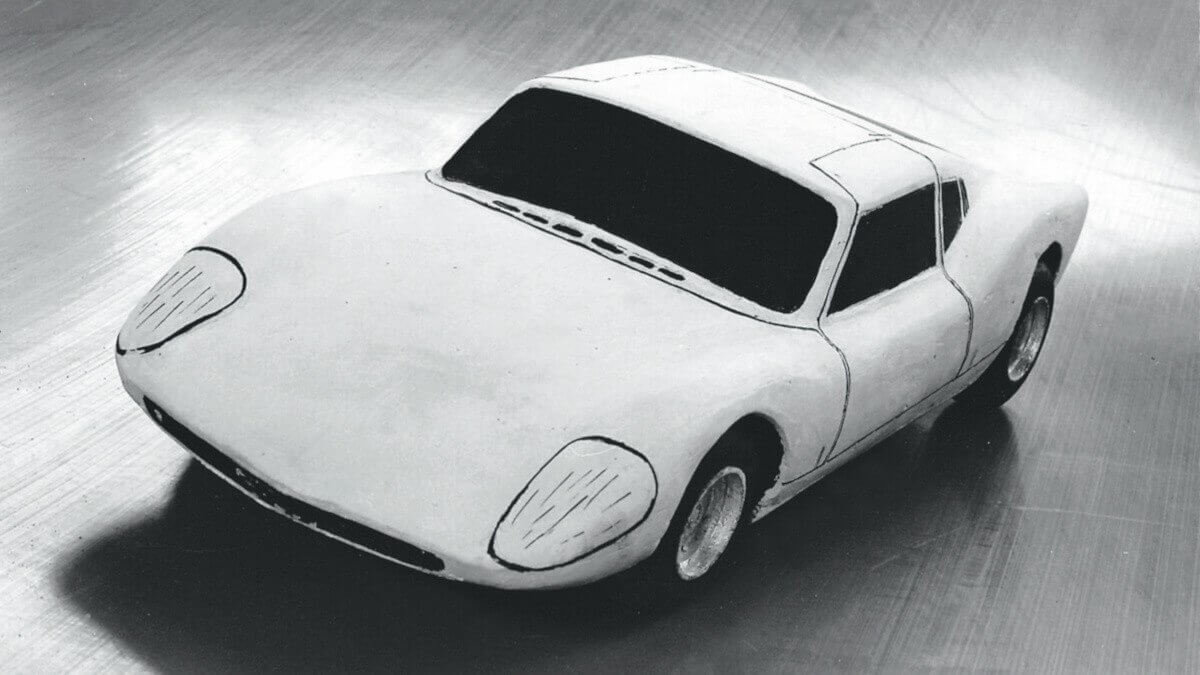

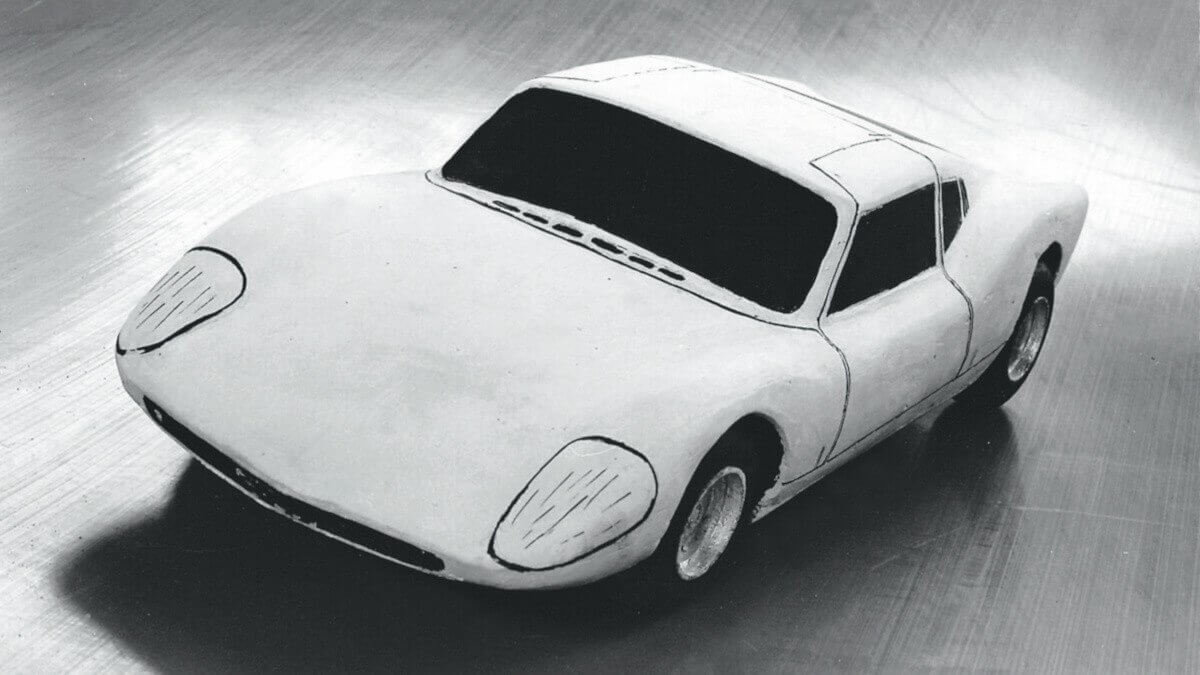

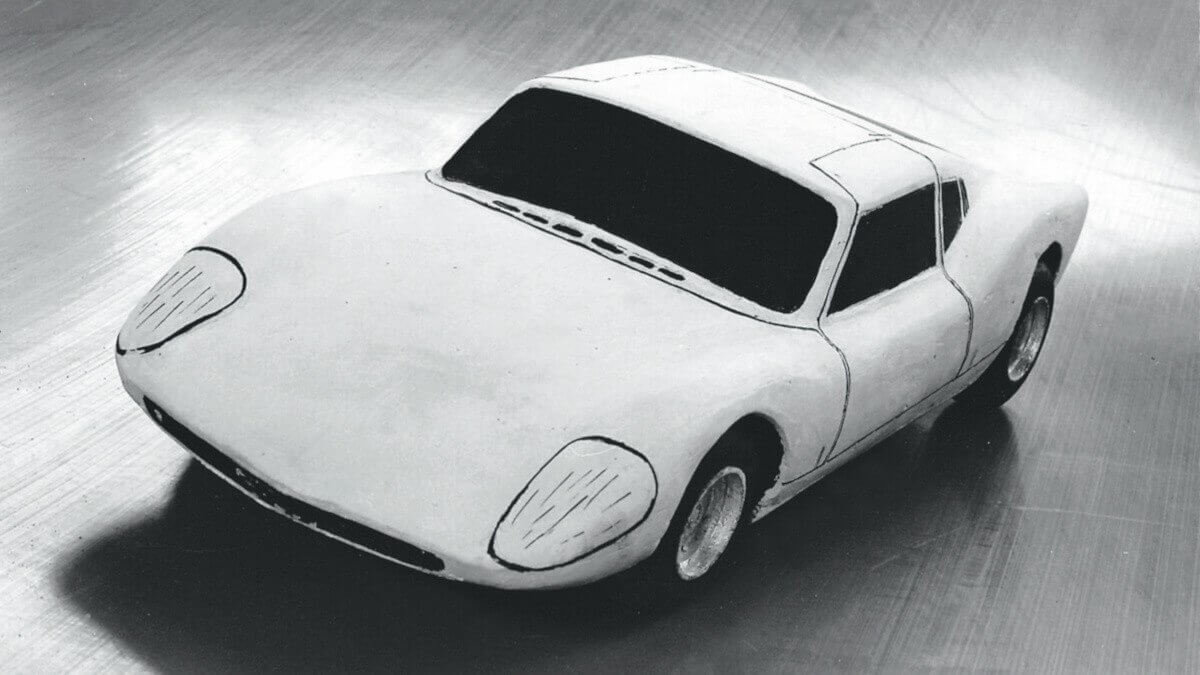

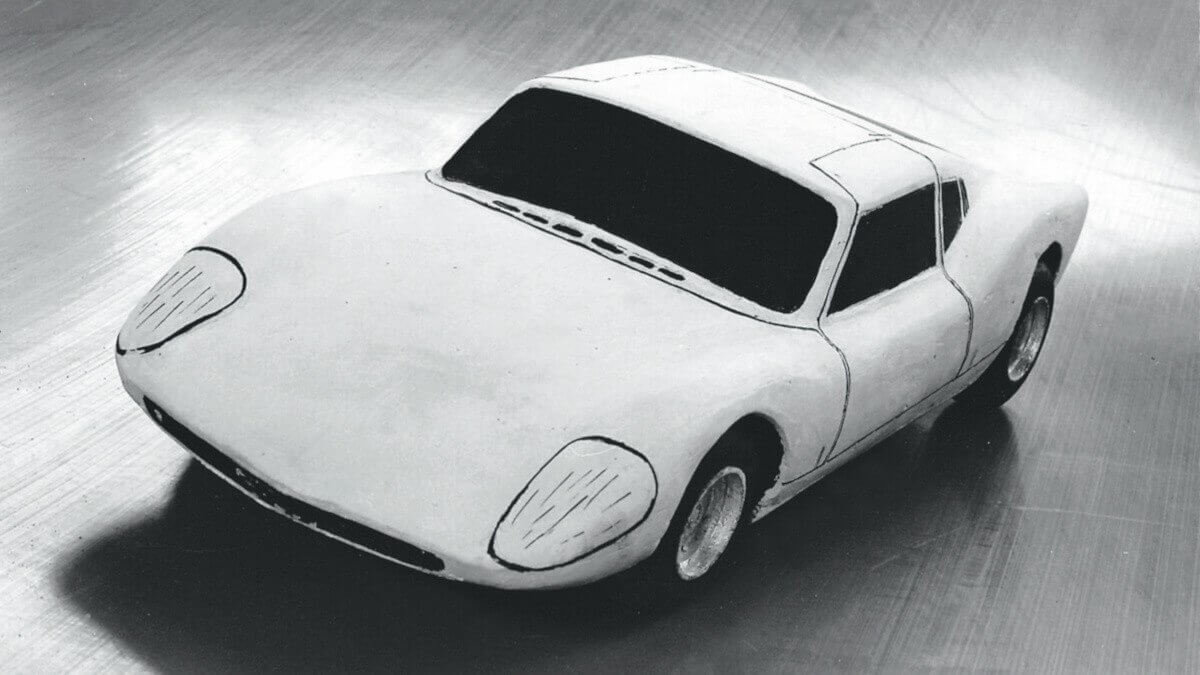

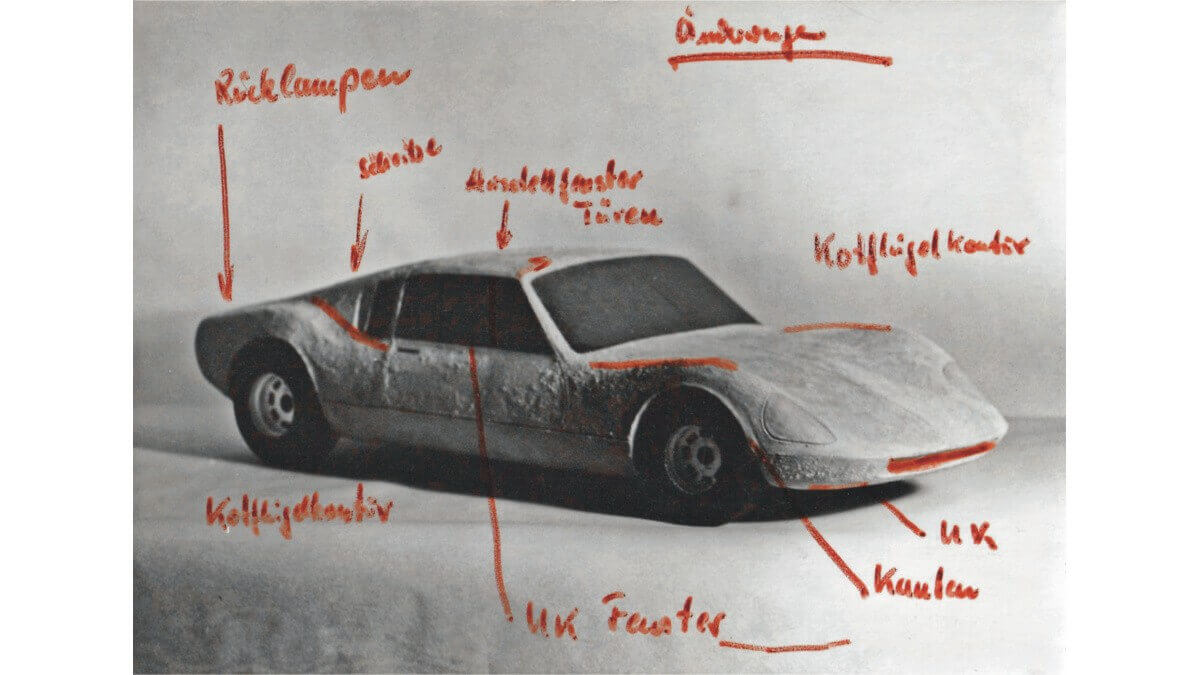

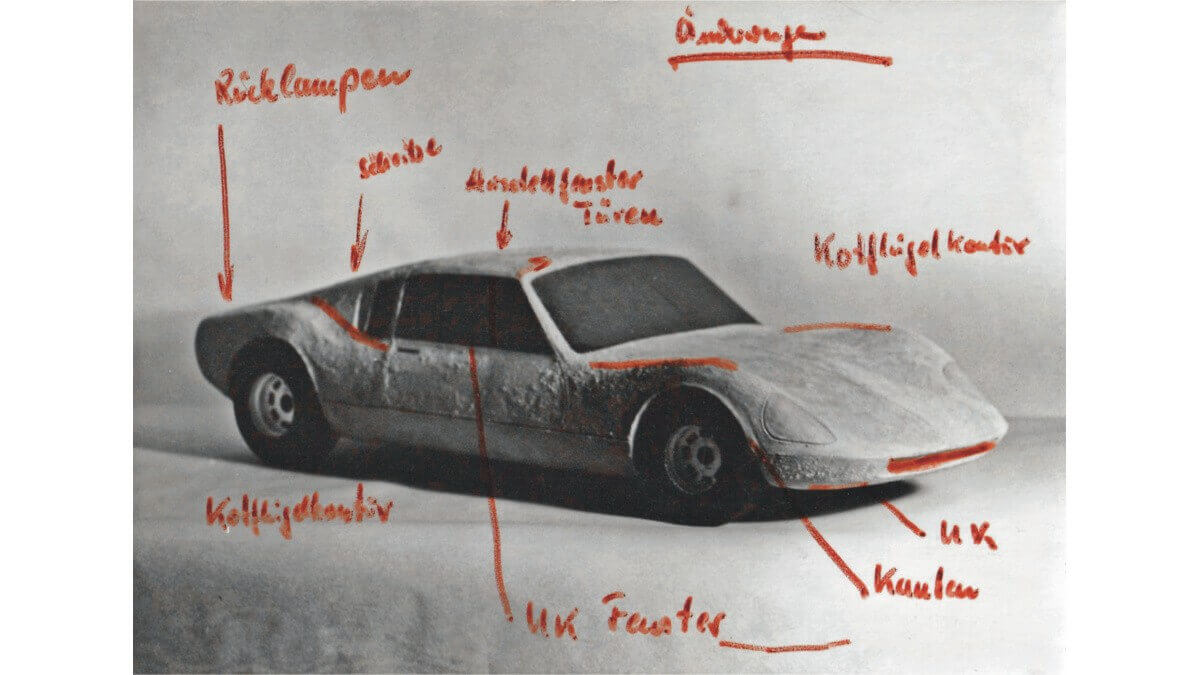

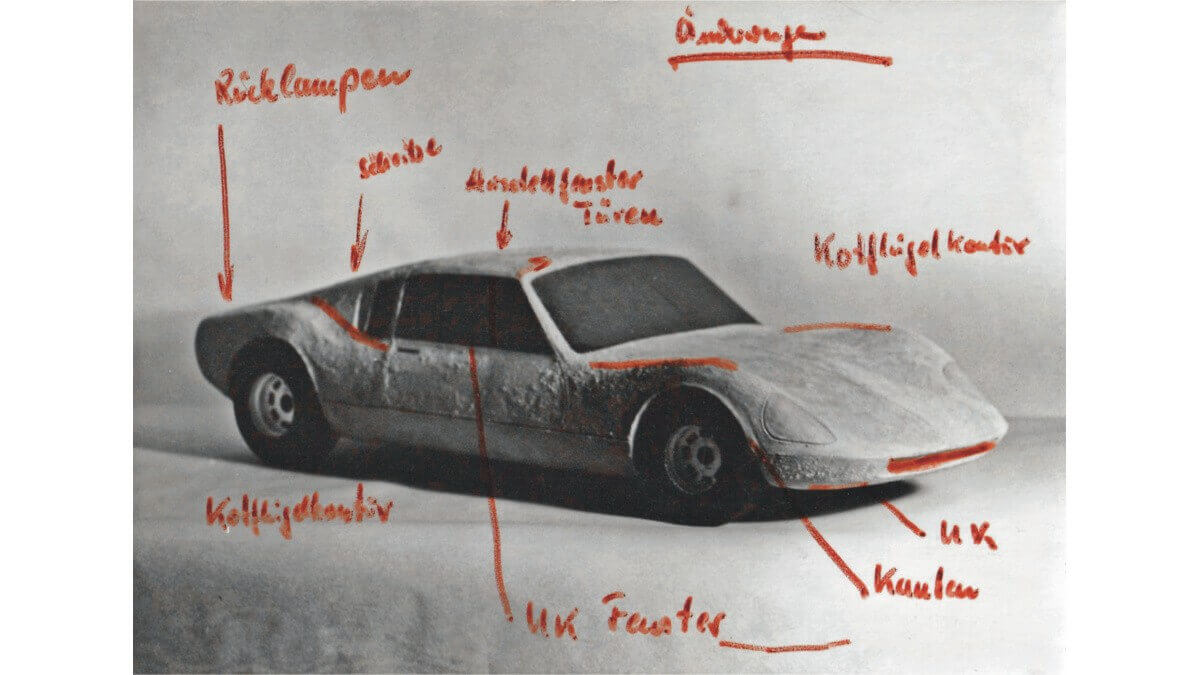

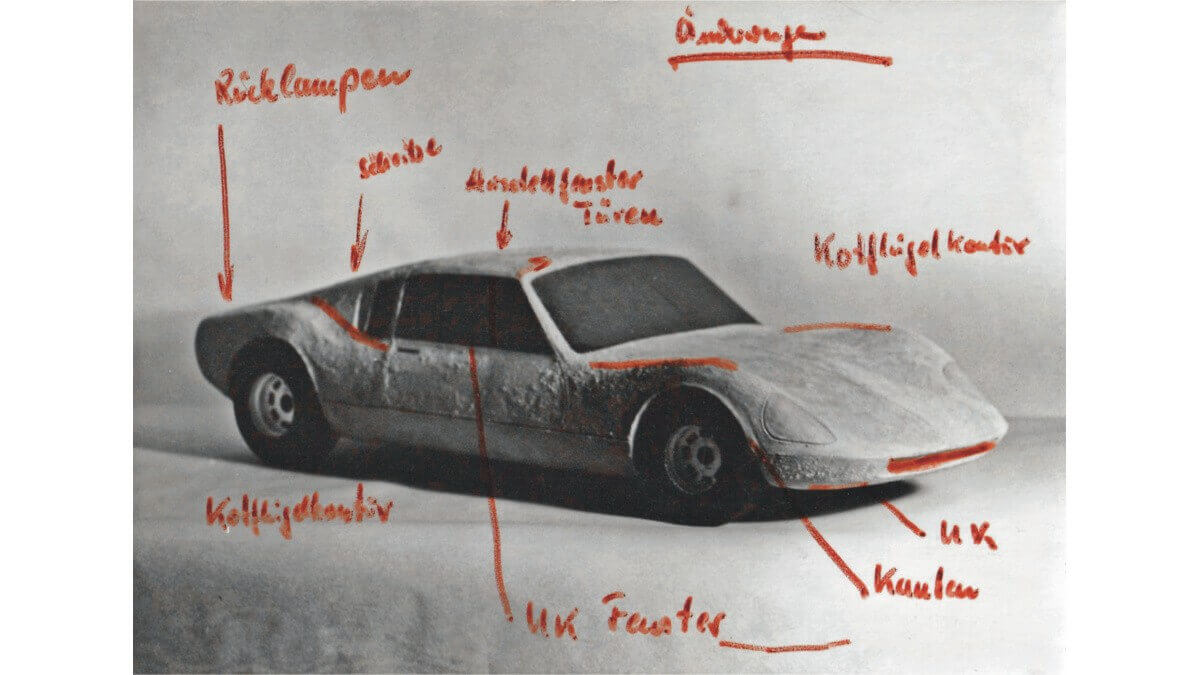

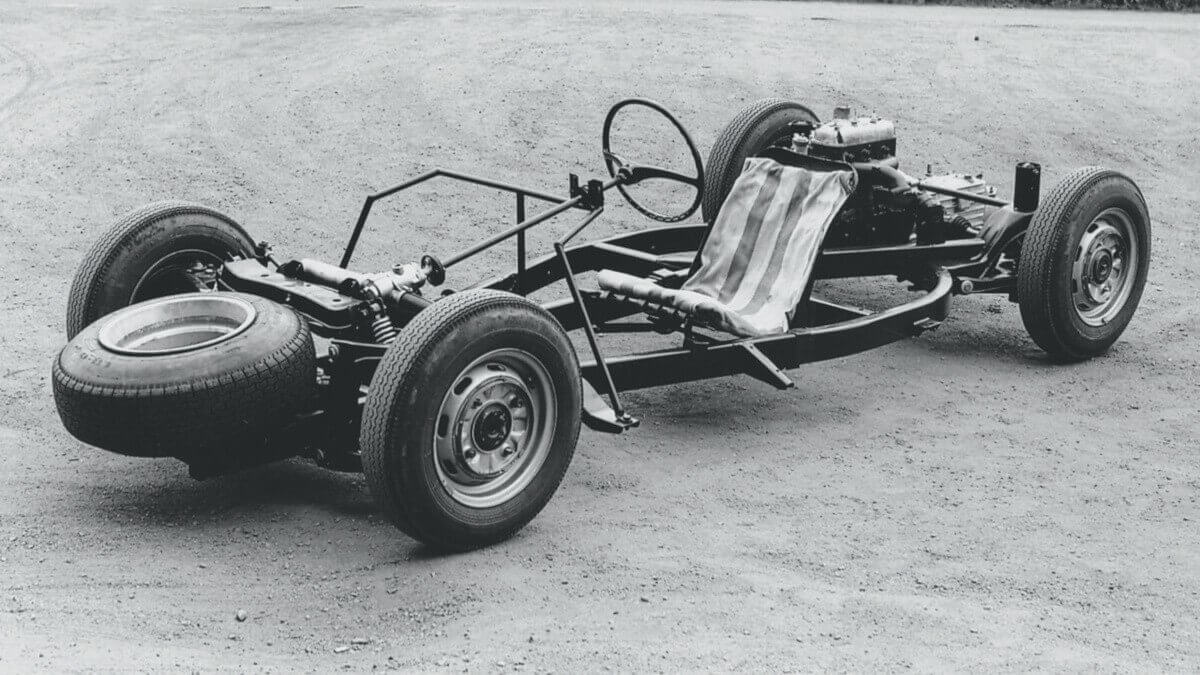

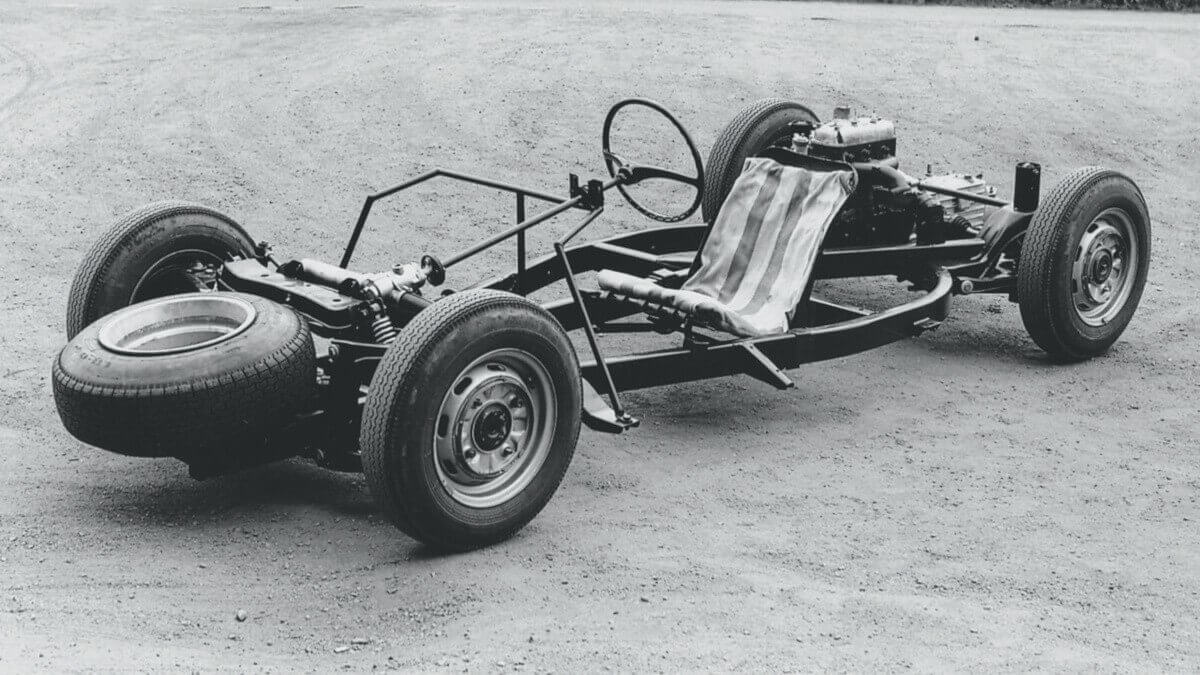

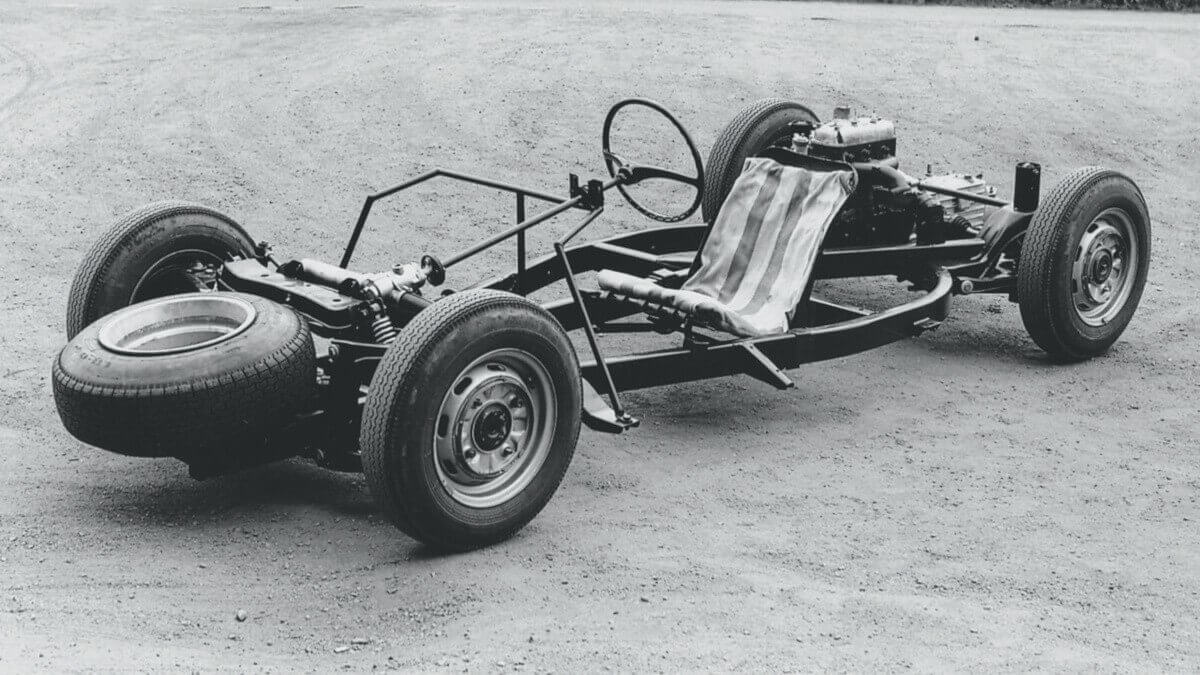

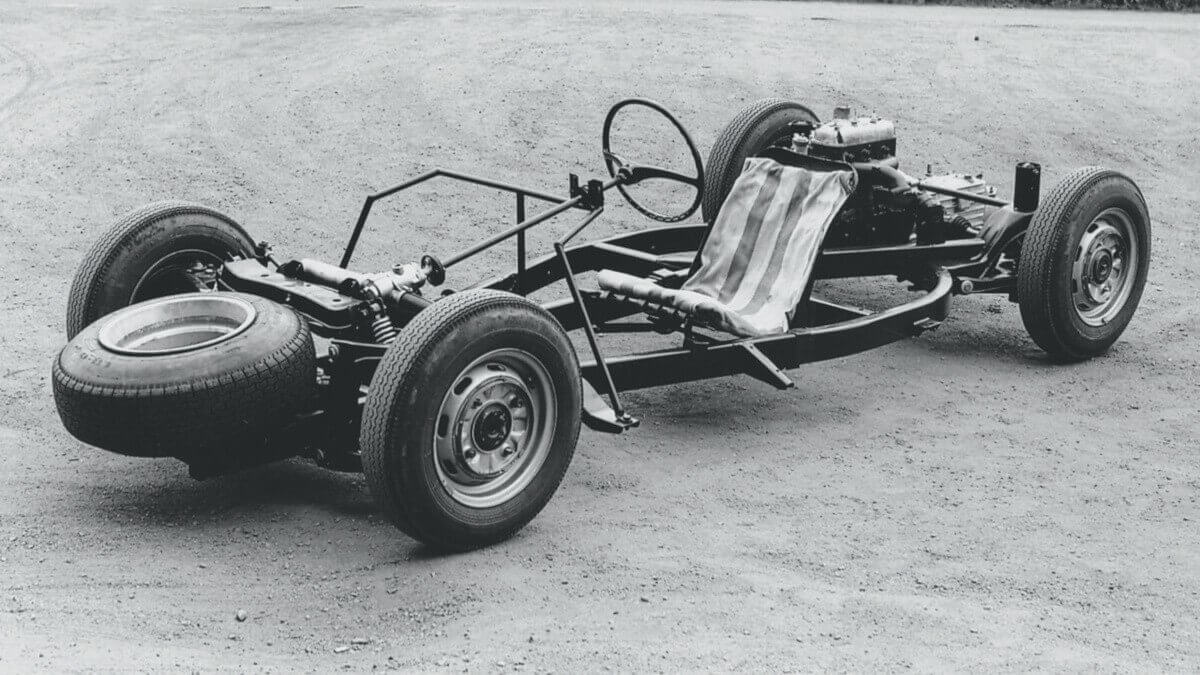

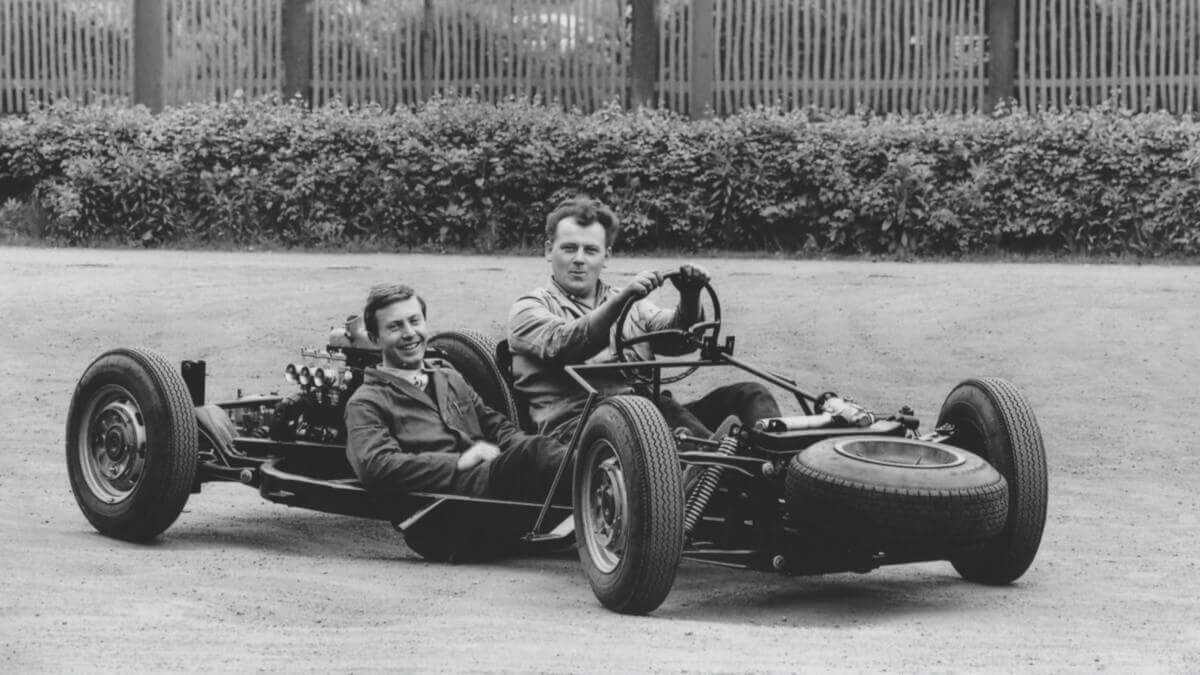

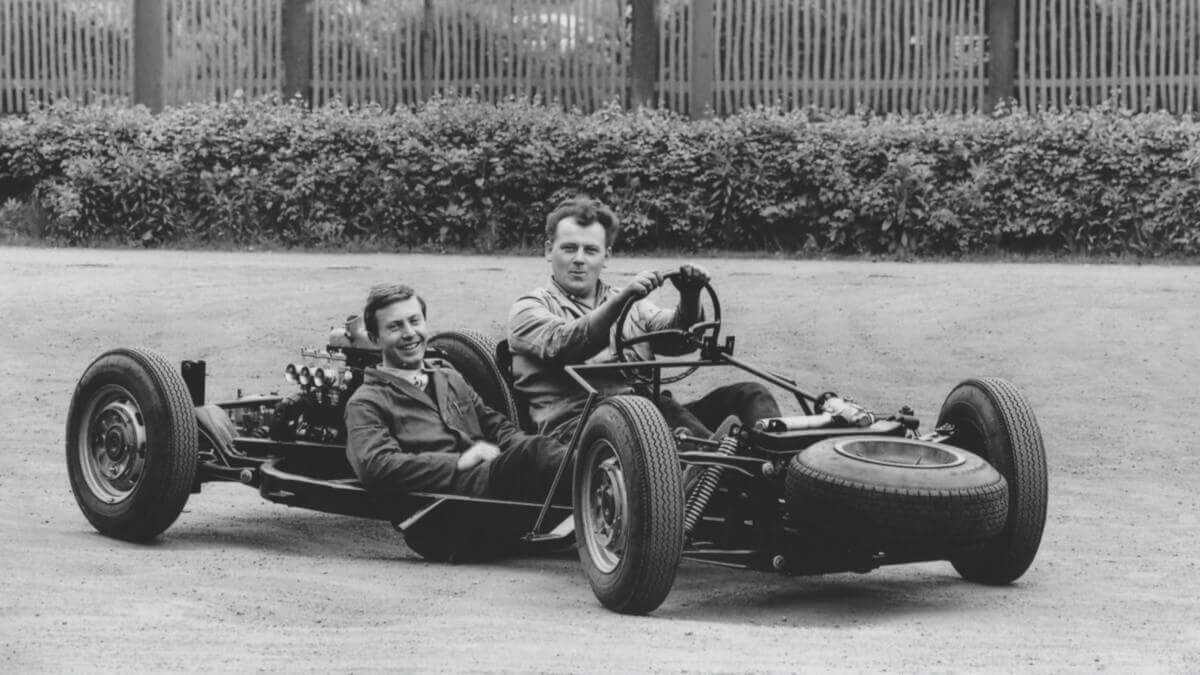

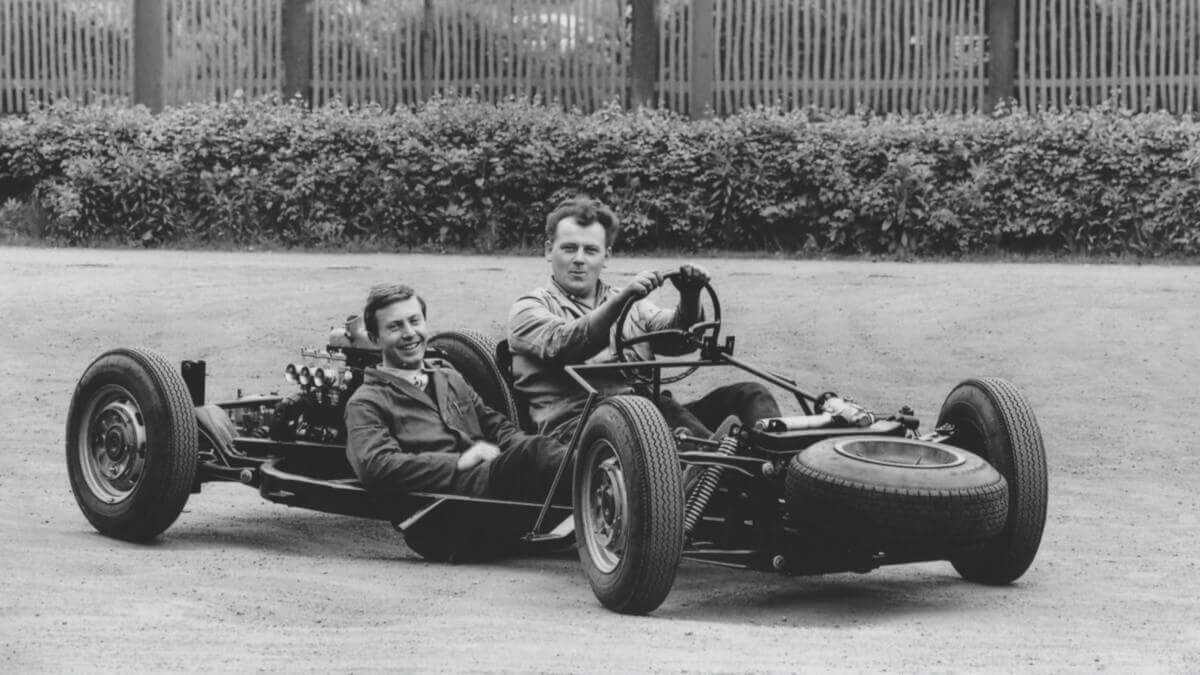

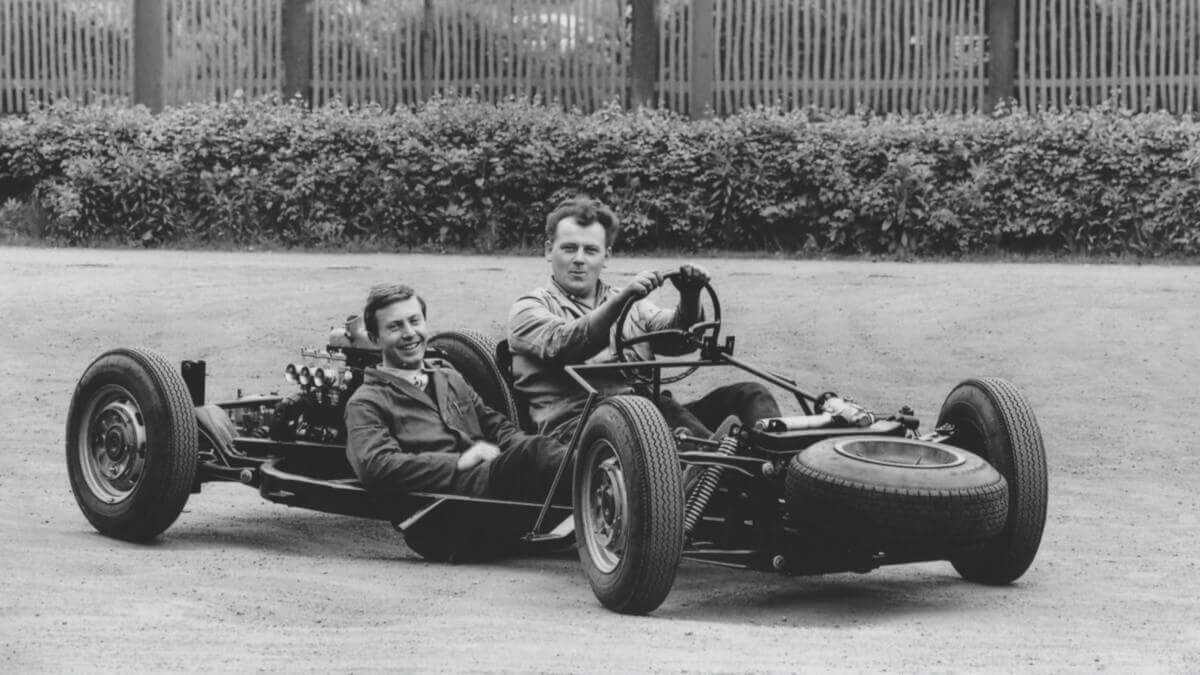

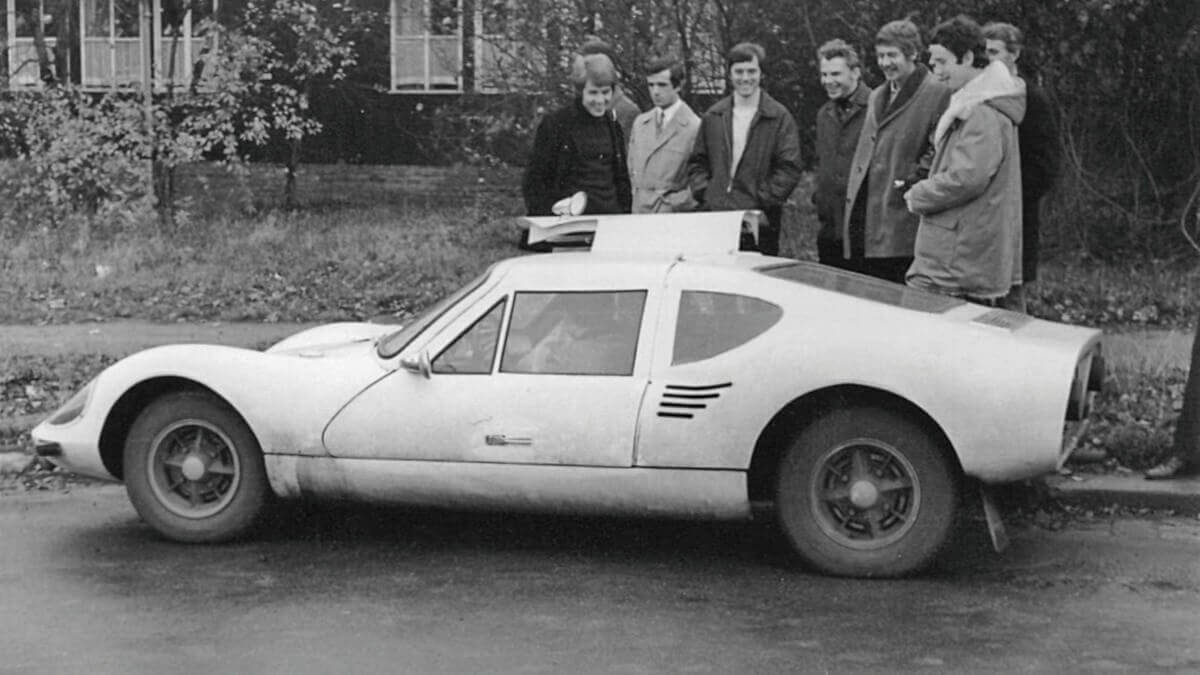

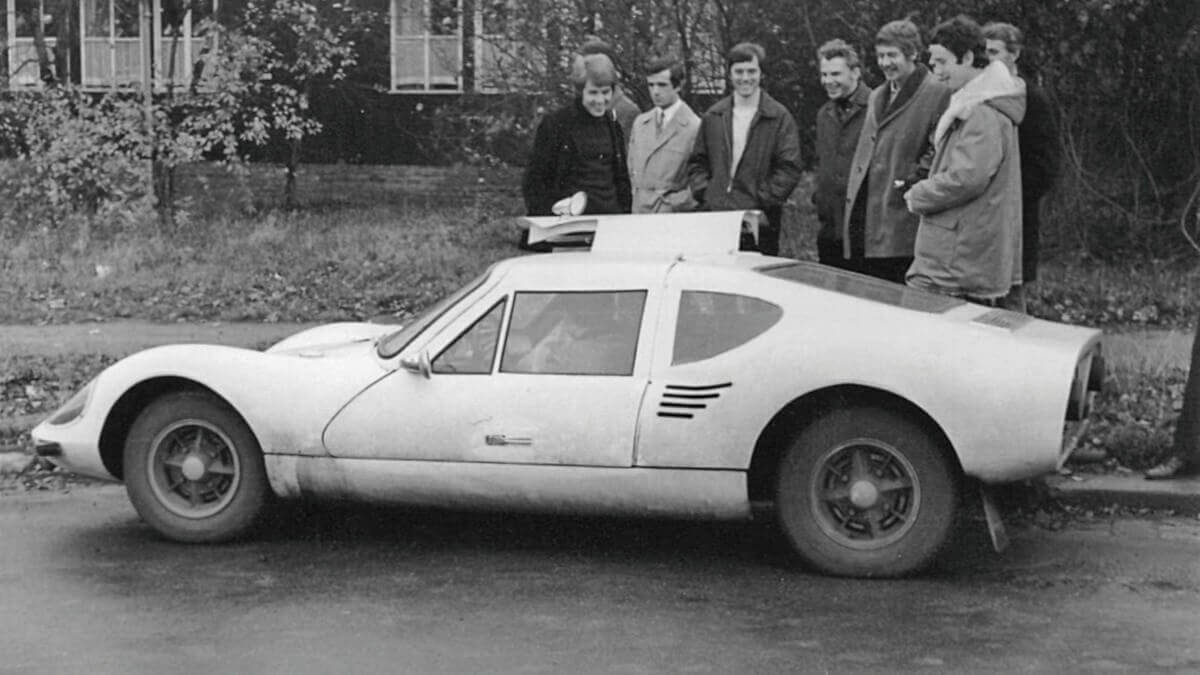

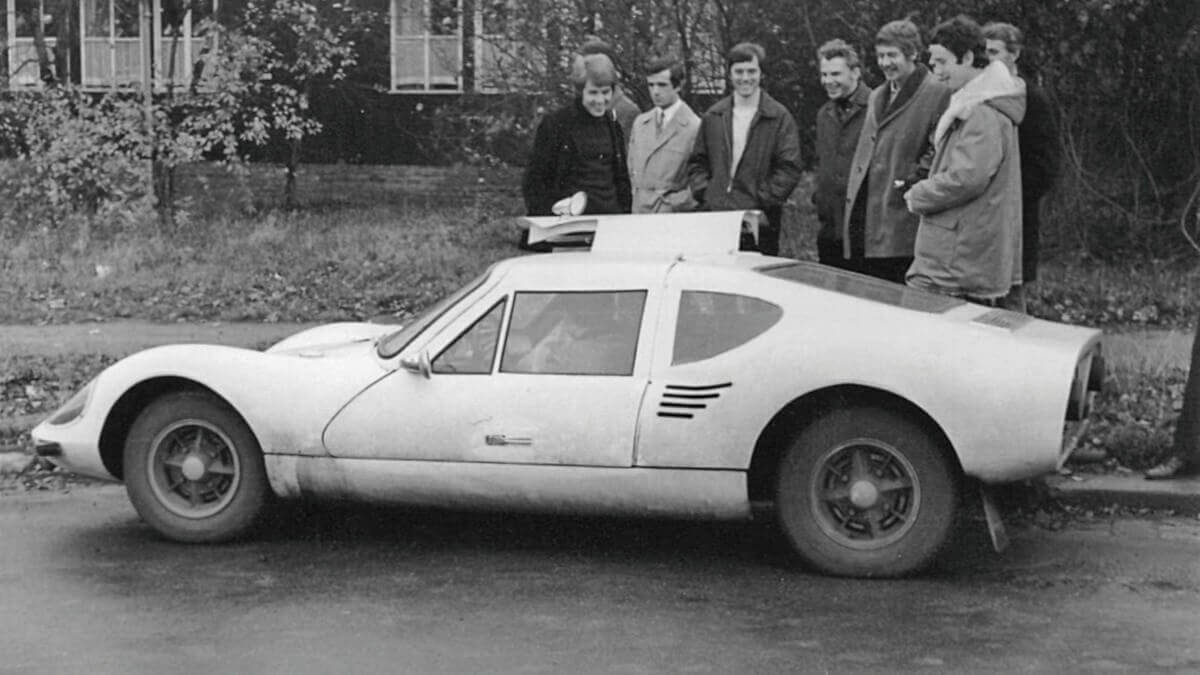

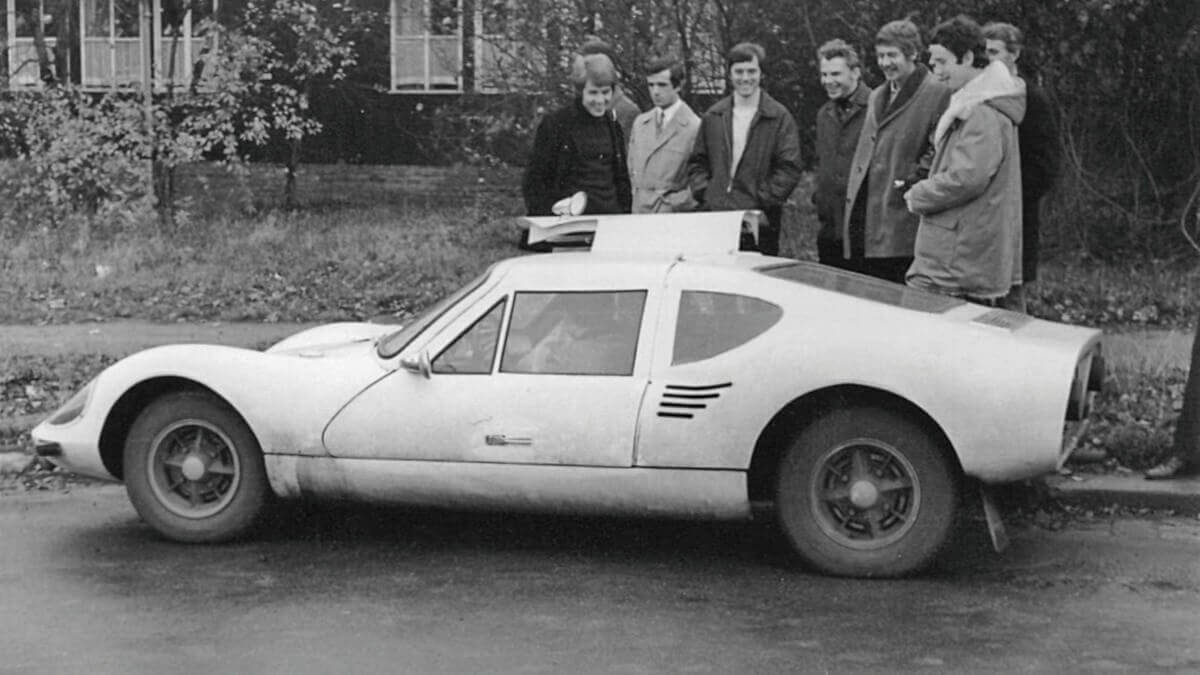

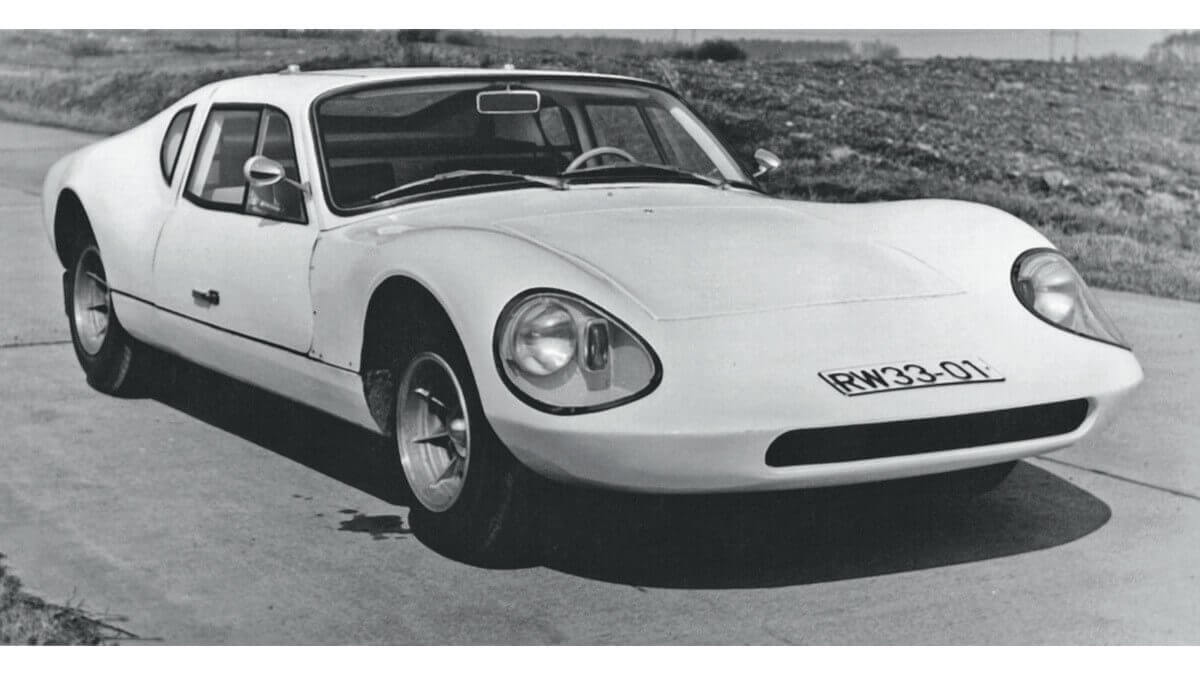

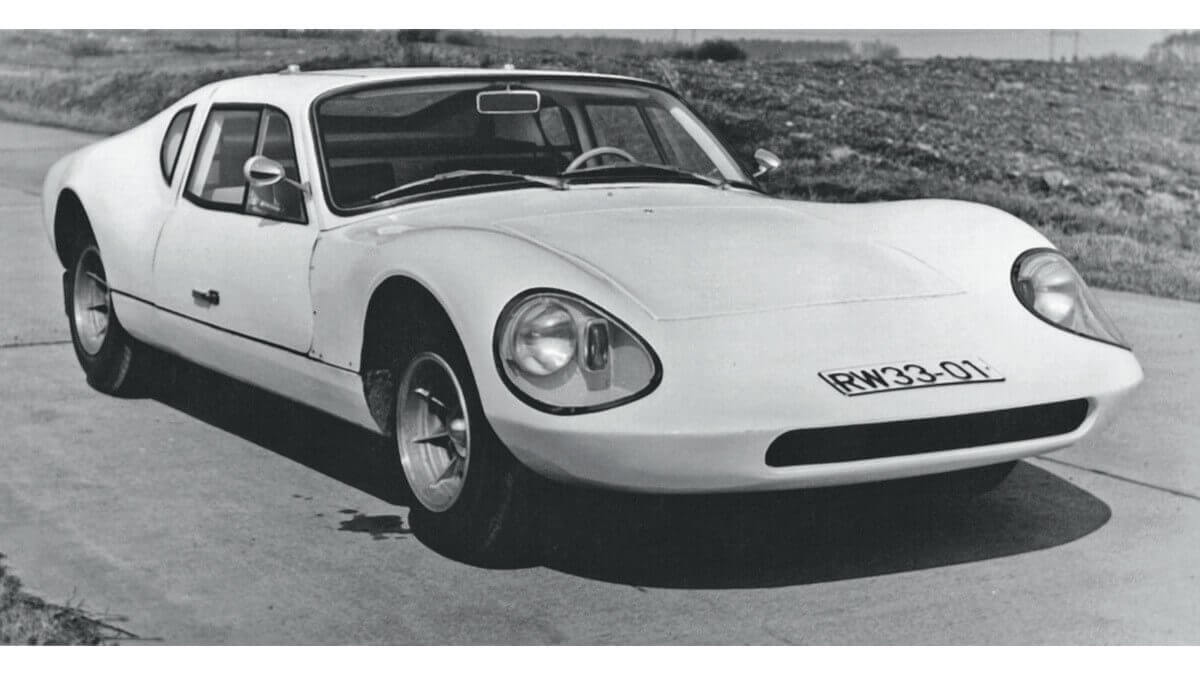

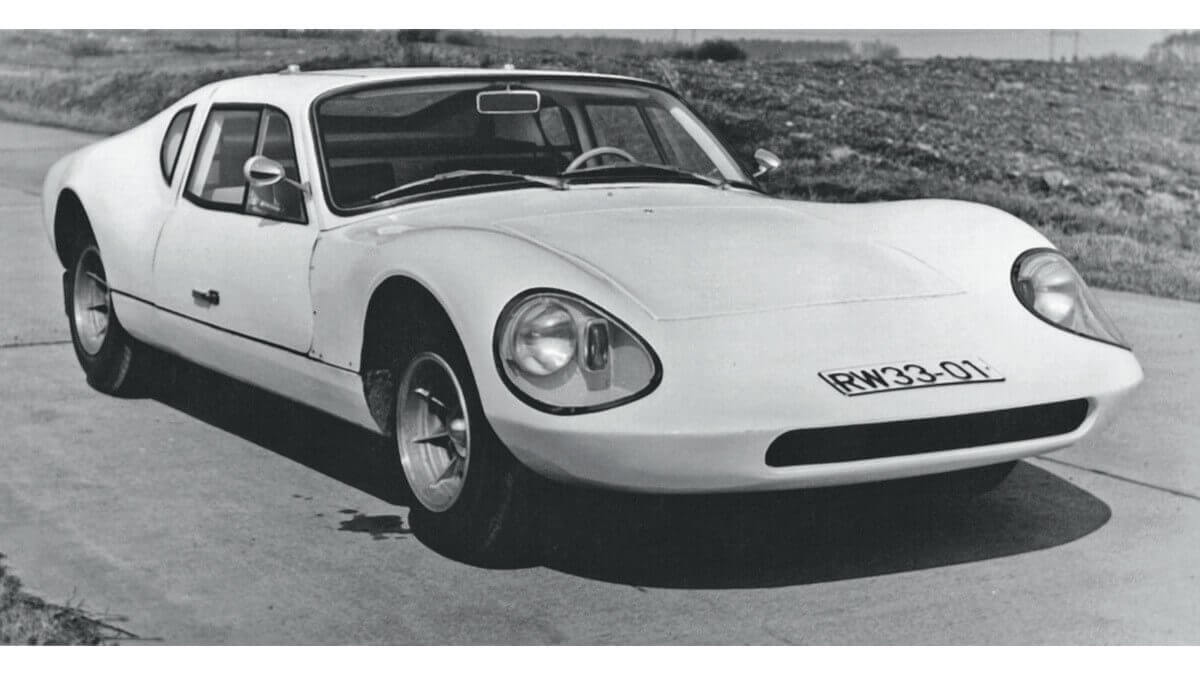

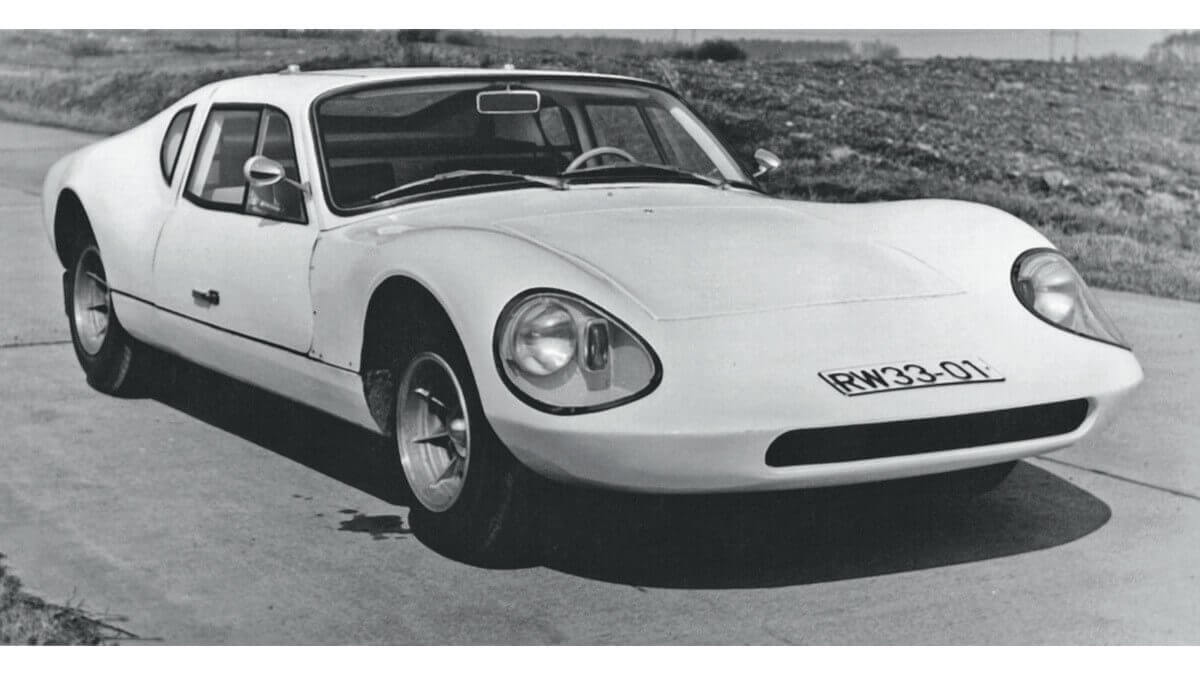

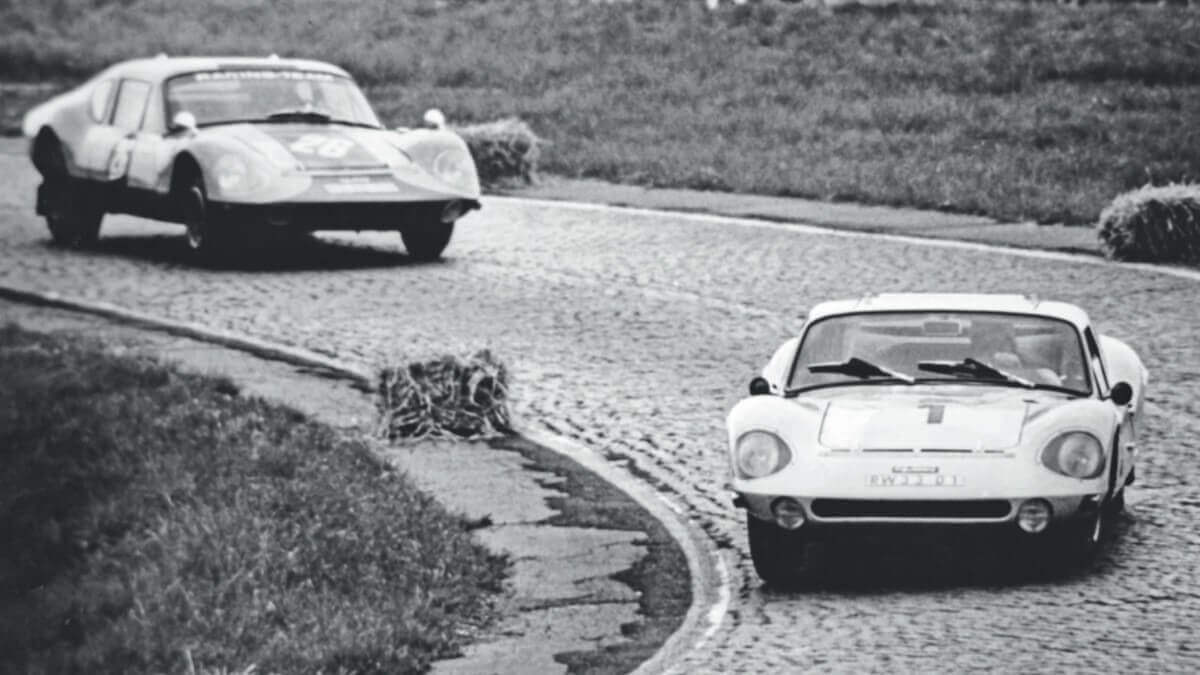

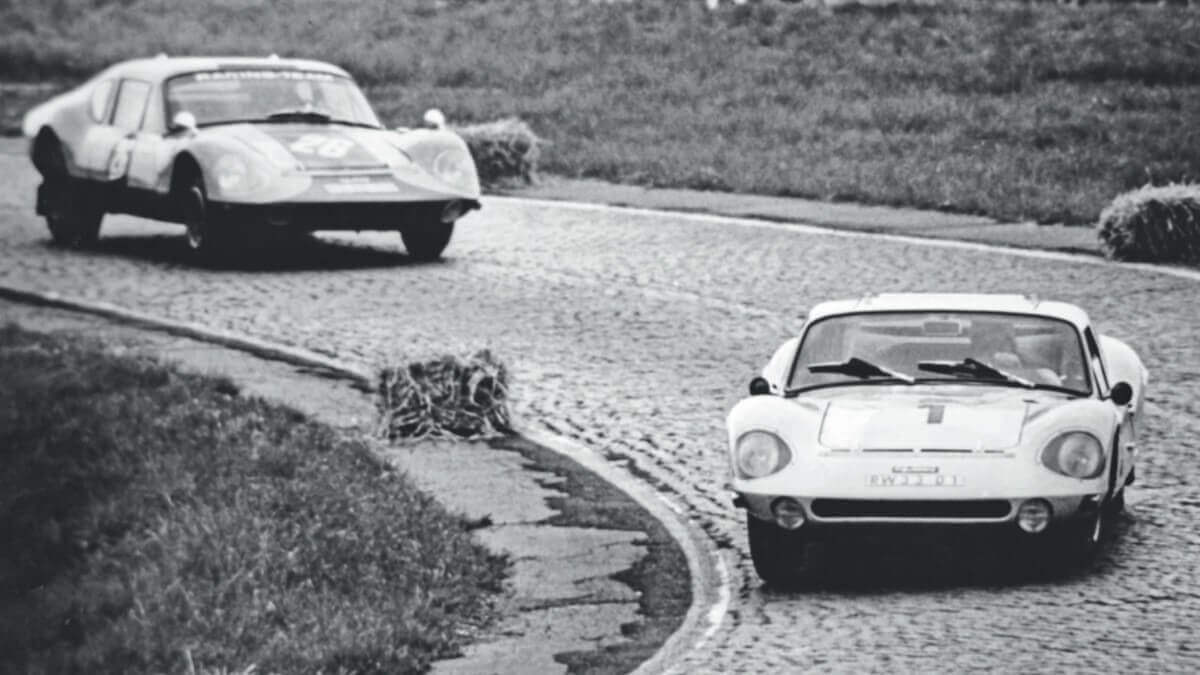

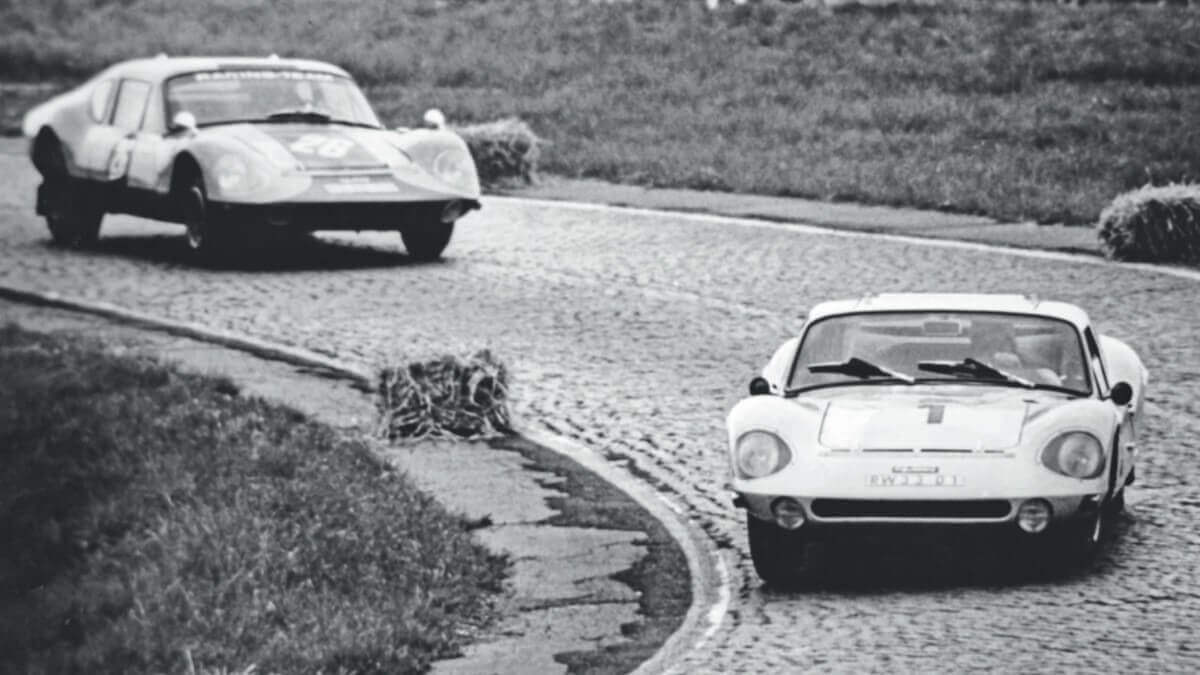

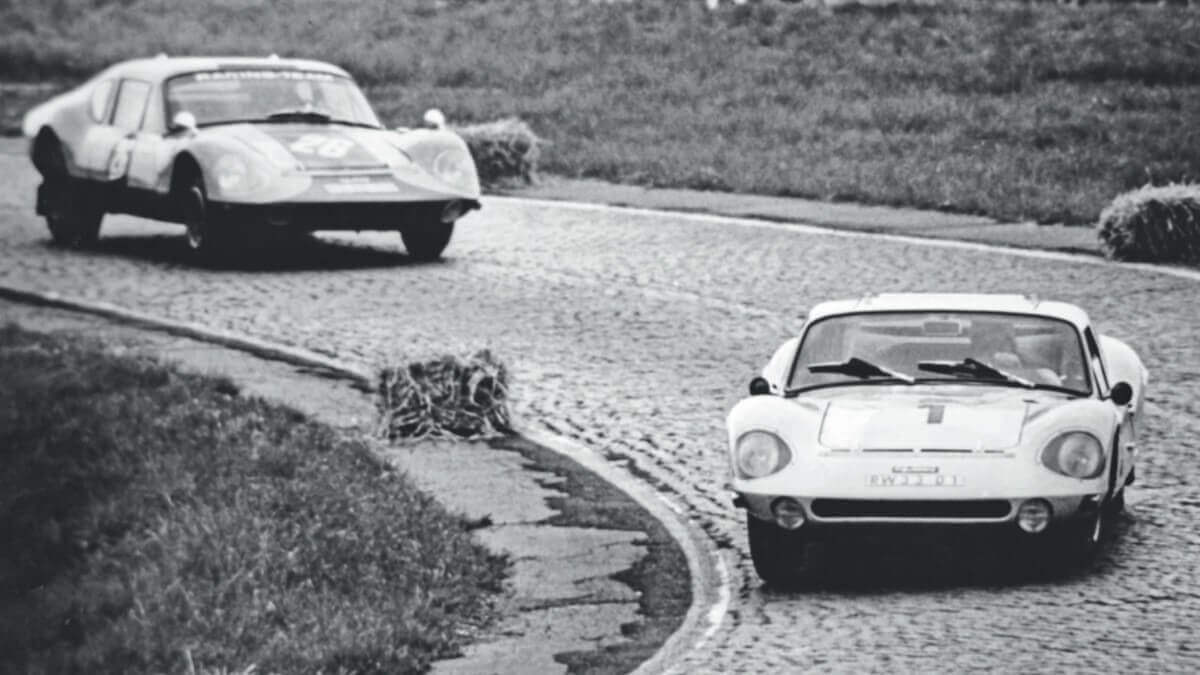

Heinz Melkus and his team were still allowed to participate in some selected racing events because of their recent success. At a Formula 3 race in Yugoslavia, he saw an early Lotus Elan, whose pure lightweight concept aroused his inner desire to develop an own street sports car with motorsport ambitions. Initially, he thought of an open two-seater roadster, which he also implemented as a plastic model in scale 1:10. However, due to the steadily decreasing supply of spare parts and the difficult to obtain contingent tickets, he had to be realistic with his project and had a look at what was achieveable with those parts that were on offer. Despite a delivery time of about six years per car for private customers, Melkus decided for the Wartburg 353 as presented in 1966 as technical basis for the sports car. However, they changed the layout from front-engined front-wheel drive to rear engine and rear-wheel drive. Also, additional struts were welded to the chassis for better rigidity stiffness. Inspired by numerous contemporary sports cars from all over the world, such as the Ford GT40 or the Porsche 904 Carrera GTS, Heinz Melkus and his sons Peter and Ulli created another 1:10 scale model of a racy sports coupé. This came visually quite close to the later production model, but was refined in various details by the designer Stefan Scheitler at Berlin Art Academy and then built as a clay model in scale 1:5. Pictures of this model were used to refine the design even more in some details like the outer lines of the fenders with red drawings. Also findings from the wind tunnel were used to modify the car. While the chassis, the roof with integrated rollbar and the doors were made of steel, the other body parts were made of fiberglass-reinforced polyester. When building the prototype, Melkus worked together with the VEB Robur plants, who had experience with this material, but normally only produced light trucks. The driveable prototype was on its wheels in just about six months. Due to the low height of only about one meter, it was decided to use roof-hinged gullwing doors to allow good entry in narrow parking spots and also in the typical low garages of the GDR.

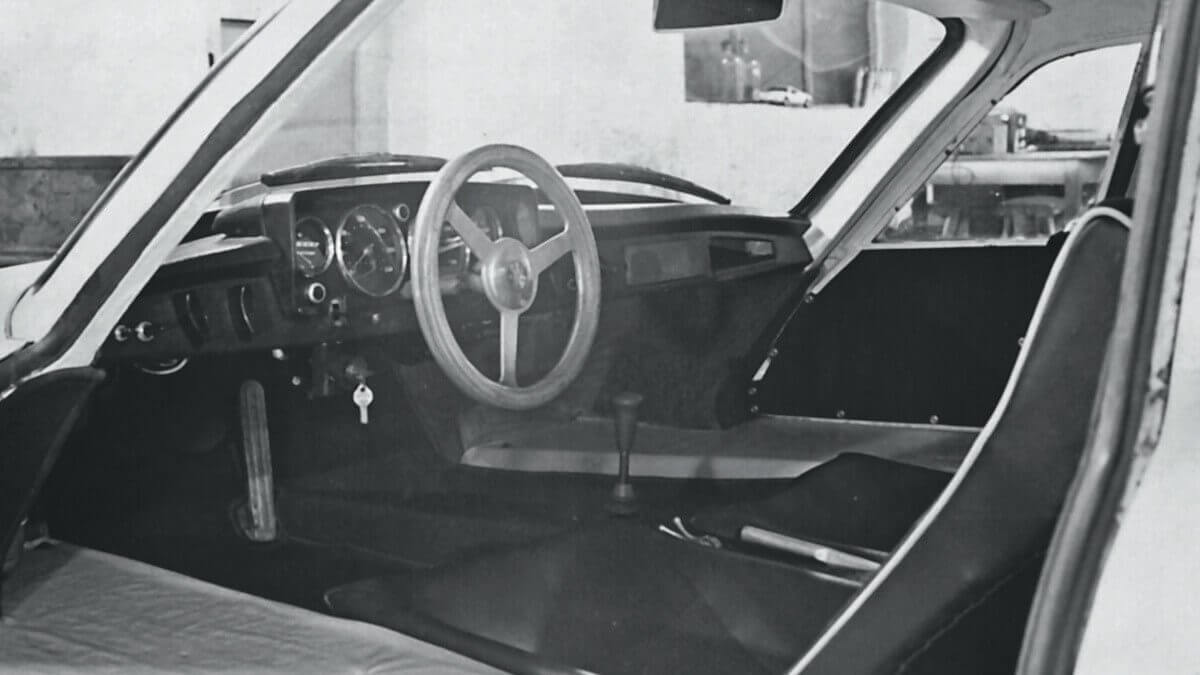

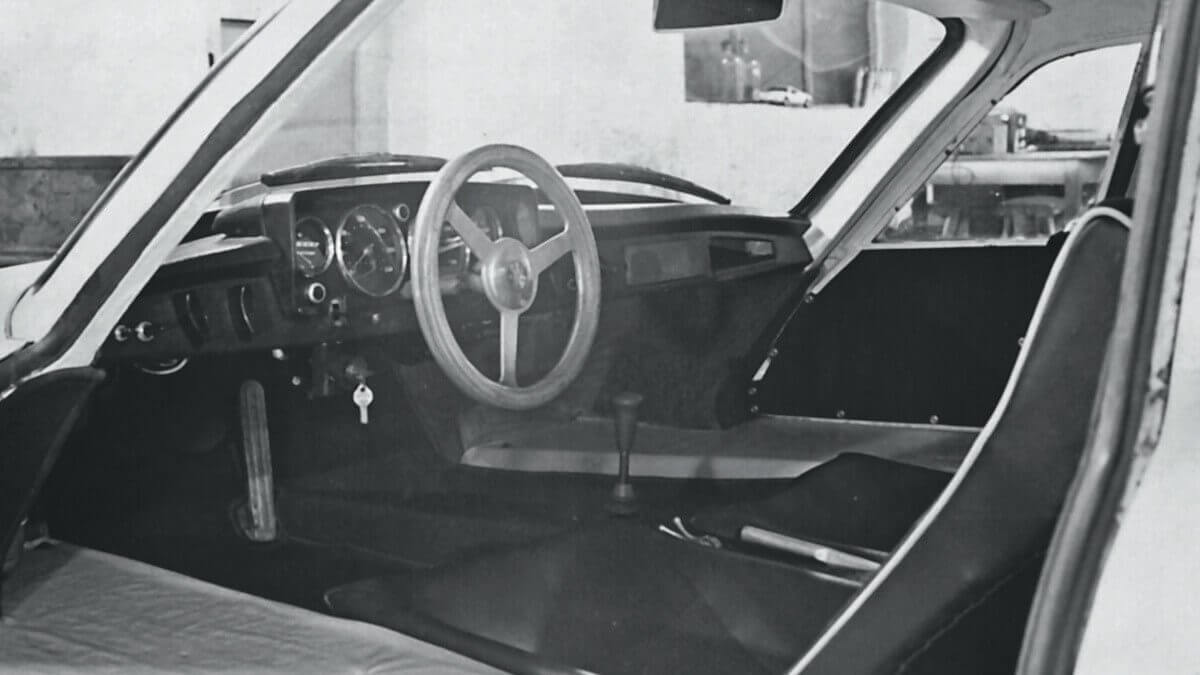

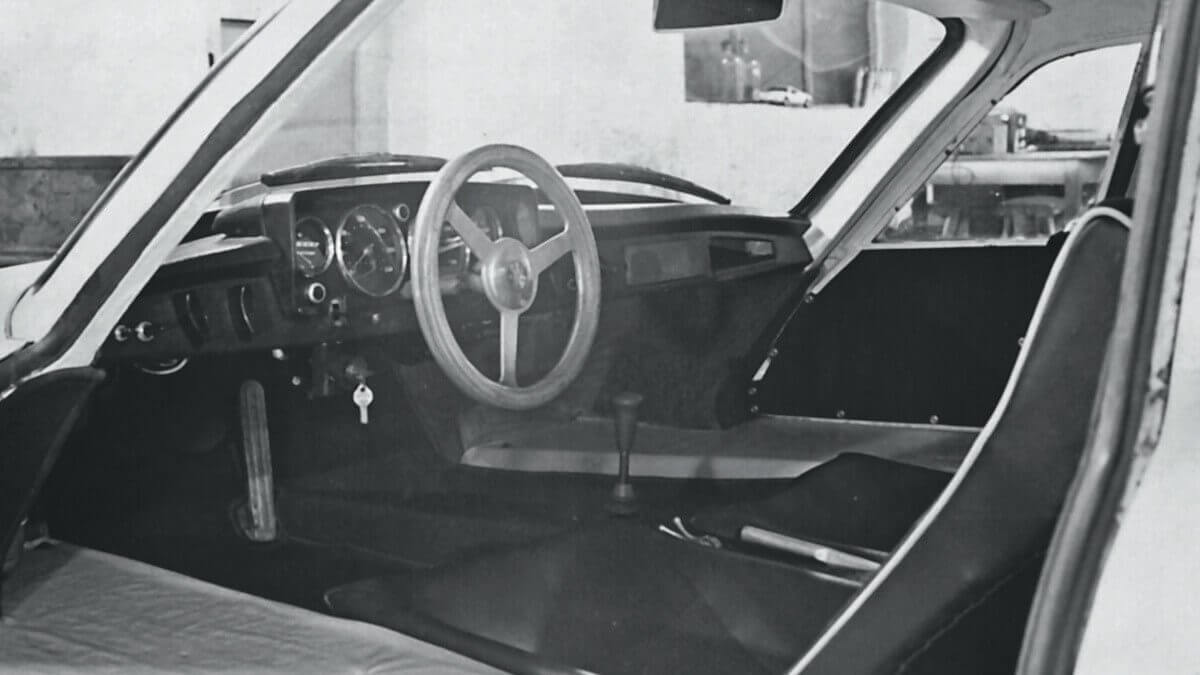

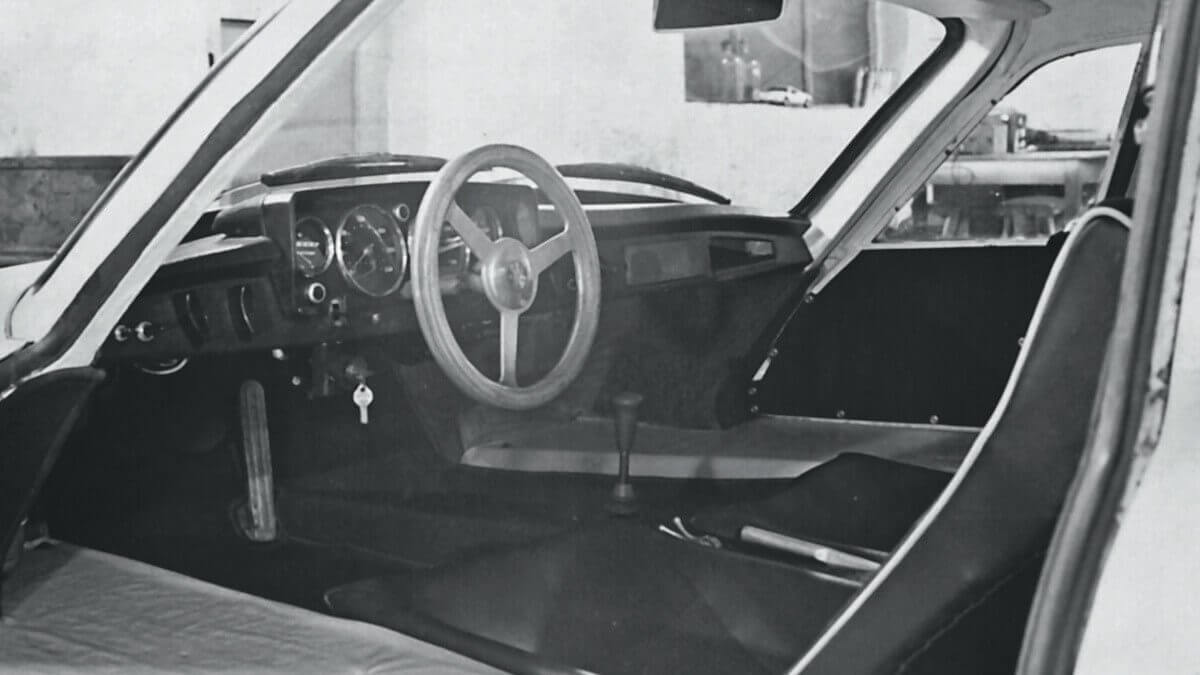

The Melkus RS1000 GT1, as the prototype was named, received a modified Wartburg engine with three carburetors and sports exhaust. The Wartburg front axle was modified with double wishbones, while the rear axle could be adopted unchanged – except of the necessary drive shafts for the rear-wheel drive. Initially Melkus used drum brakes all around, but later changed first to the disc brakes of the Polski-Fiat 125p and then to the disc brakes that were available for the Wartburg 353. The Wartburg-transmission received various modifications from the company König in Dresden. On 1 January 1969 Heinz Melkus was finally able to drive his new vehicle for the first time. Various improvements were made within the next few months until the car was first shown publically at the ‘hallensia mobile’ event in Halle/Saale in April of the same year. After that it was time to prepare the RS1000 for series production. For this purpose, first a permit from the Kraftfahrzeugtechnisches Amt (KTA, motor vehicle technical office) of the GDR had to be obtained. This office demanded numerous changes after they had inspected the prototype, for example the arrangement of the front indicator lights, a bigger sized rear side window and other details. After these points were processed on the prototype GT1, the approval was written directly by the IFA-Kombinat (Industrieverband Fahrzeugbau, industrial association of vehicle construction) in Karl-Marx-Stadt (today Chemnitz), so that the production could start in 1970. The selling price was set at 29,800 Mark, while for example a Trabant P601 Standard was listed at 8,500 Mark. In addition, authorities requested a membership in the ADMV (Allgemeiner Deutscher Motorsport Verband, General German Motorsport Association) of the GDR and regular racing participation of the Melkus owners. Next to that, the prototype GT1, which was further developed with improvements from time to time, had to be made available for the KTA as a reference vehicle several weeks each year in order to extend its production approval.

In the production version, the Melkus RS1000 stood on steel wheels from Wartburg while the racing version received ultra-light rims made of electron. Inside, the GT1 still showed the dashboard of the Wartburg and Trabant-derived seats, which were soon swapped for an own dashboard design and self-developed sports seats, whose upholstery was done by a RS1000 owner from Ribnitz-Damgarten. The high degree of improvisation, that was necessary in the GDR of that time, is evident when looking at the exterior mirrors of early cars, which were made of the housing of a bicycle headlamp and a round mirror glass cut out from a much bigger truck mirror glass. The chassis frames came directly from the VEB Metallverarbeitung Maxen, which was responsible for the regeneration of Wartburg chassis after accidents or rust through within the GDR. They also supplied the material for the additional struts, which were hand-made and lightly welded in place by Melkus. Afterwards the chassis went back to Maxen, where the struts were fully welded by using CO2 inert gas welding machines. Engines, axles and other components were picked up by truck from the spare parts warehouse of VEB Automobilwerke Eisenach – while Melkus on the other hand often left some gifts for the employees there, for example beer crates. Later in the 1970s, the shortage economy of the GDR also struck the sports car maker sustainably. They were forced to buy parts for high prices at the official Wartburg dealers or to acquire them in strange swaps. For example, once they got two axles for a new car by giving two places in the driving school, which Heinz Melkus operated next to his carmaking business.

For the bodies, that were initially manufactured by the VEB Robur in Bautzen and later by Röber (also from Bautzen), all available paint colors from GDR vehicles could be chosen. However, there were also some Melkus vehicles in metallic paints from Western Europe, which were specially organized for this purpose in sufficient quantities by the later owners. Due to the ever more difficult parts supply, Heinz Melkus finally finished the production in 1979 after exactly 101 copies of the RS1000. Meanwhile, there had been efforts to give the sports car significantly more power by coupling two Wartburg three-cylinder engines. However, the synchronization turned out to be extremely demanding. Other customers tried classical tuning by drilling the cylinders to increase the displacement from 998 to 1,100 cubic centimeters, which increased the power from 70 to more than 90 hp. But this treatment also caused thermal problems especially under race conditions. Some members of the ADMV got their hands on the so-called ‘Leutert engines’, which had been developed for the rally versions of the Wartburg 353. In addition, there were customer conversions to Lada technology or even the specially imported engine of a BMW 2002. Only on paper, there was also the idea of putting a Tatra V8 into the little Melkus. This might have resulted in a rear-heavy car without good driveability.

Thirty-five years after the production ended, Melkus still had its name in Dresden: as a dealership for BMW who occasionally restored old RS1000. During one of these restorations the idea came along to start the production of this classic sports coupé once again. The BMW dealership was sold, Heinz Melkus died and Peter Melkus together with his son Sepp started to work on this idea intensively. After they found enough new suppliers, searched and bought re-usable Wartburg parts (as that brand doesn’t exist anymore since 1991) and, due to technical advancements over the last 30 years, changed some components to new materials, a new prototype was built, which technically uses the state of the last RS1000 from 1979. However, now also the doors are made from fiberglass-reinforced plastic. They even found an old mold for the electron wheels, which was restored and good enough to replicate 80 new rims. At prices starting at around 90,000 euros, the new edition of the Melkus RS1000 is available to customers. First they produced 15 copies of the ‘Heinz Melkus Edition’ and afterwards to this day another 15 street versions plus ten more powerful RS1000 GTRs, the new non-street legal racing version for the RS1000 Cup, offered since 2013. Among the 30 road vehicles are five ‘RS1600’, which received a 1.6-liter four-cylinder VW engine at the request of their customers. Meanwhile, the limited edition production of the RS1000 continues, so interested parties still can order a new car today. The successor RS2000, which debuted at the IAA 2009 and was based on the Lotus Elise, was discontinued after only a few cars due to lack of interest.

Images: Melkus